ENERGY_EFFICIENCY_IN_ELECTRICAL_UTILITIES

(Chapter 3:Compressed Air System)

Introduction

Air compressors account for significant amount of electricity used in Indian industries. Air compressors

are used in a variety of industries to supply process requirements, to operate pneumatic tools and

equipment, and to meet instrumentation needs. Only 10-30% of energy reaches the point of end-use

(Figure 3.1), and balance 70-90% of energy of the power of the prime mover being converted to

unusable heat energy and to a lesser extent lost in form of friction, misuse and noise.

Compressor Types

Compressors are broadly classified as: Positive displacement compressor and Dynamic compressor

(Figure 3.2).

Positive displacement compressors increase the pressure of the gas by reducing the volume. Positive

displacement compressors are further classified as reciprocating and rotary compressors.

Dynamic compressors increase the air velocity, which is then converted to increased pressure at the

outlet. Dynamic compressors are basically centrifugal compressors and are further classified as radial

and axial flow types.

The flow and pressure requirements of a given application determine the suitability of a particulars

type of compressor.

Positive Displacement Compressors

Reciprocating Compressors

Reciprocating compressors (Figure 3.3) are the most widely used type for air compression. They are

characterized by a flow output that remains nearly constant over a range of discharge pressures. Also,

the compressor capacity is directly proportional to the speed. The output, however, is a pulsating one.

Reciprocating compressors are available in many configurations, the four most widely used of which

are horizontal, vertical, horizontal balance-opposed and tandem. Vertical type reciprocating compressors

are used in the capacity range of 50 — 150 cfm. Horizontal balance opposed compressors are used in

the capacity range of 200 — 5000 cfm in multi-stage design and up to 10,000 cfm in single stage designs.

Reciprocating compressors are also available in variety of types:

¢ Lubricated and non-lubricated

¢ Single or multiple cylinder

¢ Water or air-cooled

¢ Single or multi stage

In the case of lubricated machines, oil has to be separated from the discharge air. Non-lubricated

compressors are especially useful for providing air for instrumentation and for processes which require

oil free discharge. However non-lubricated machines have higher specific power consumption (kW/

cfm) as compared to lubricated types.

Single cylinder machines are generally air-cooled, while multi-cylinder machines are generally water

cooled, although multi-stage air-cooled types are available for machines up to 100 kW. Water-cooled

systems are more energy efficient than air-cooled systems.

Two stage machines are used for high pressures and are characterized by lower discharge temperature

(140 to 160°C) compared to single-stage machines (205 to 240°C). In some cases, multi-stage machines

may have a lower specific power consumption compared to single stage machines operating over the

same total pressure differential. Multi-stage machines generally have higher investment costs,

particularly for applications with high discharge pressure (above 7 bar) and low capacities (less than

25 cfm). Multi staging has other benefits, such as reduced pressure differential across cylinders, which

reduces the load and stress on compressor components such as valves and piston rings.

Rotary Compressors

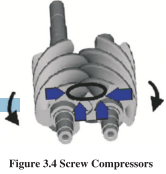

Rotary compressors (Figure 3.4) have rotors in place of pistons and give a continuous, pulsation free

discharge air. They are directly coupled to the prime mover and require lower starting torque as

compared to reciprocating machine. They operate at high speed and generally provide higher throughput

than reciprocating compressors. Also they require smaller foundations, vibrate less, and have a lower

number of parts - which means less failure rate.

Among rotary compressor, the Roots blower (also called as lobe

compressor) and screw compressors are among the most widely used.

The roots blower is essentially a low-pressure blower and is limited

to a discharge pressure of | bar in single-stage design and up to 2.2

bar in two stage design.

The most common rotary air compressor is the single stage helical {

or spiral lube oil flooded screw air compressor. These compressors

consist of two rotors, within a casing where the rotors compress the

air internally. There are no valves. These units are basically oil cooled

(with air cooled or water cooled oil coolers) where the oil seals the internal clearances. Since the

cooling takes place right inside the compressor, the working parts never experience extreme operating

temperatures. The oil has to be separated from discharge air. Because of the simple design and few

wearing parts, rotary screw air compressors are easy to maintain, to operate and install.

The oil free rotary screw air compressor uses specially designed air ends to compress air without oil

in the compression chamber producing true oil free air. These compressors are available as air-cooled

or water cooled types and provide the same flexibility as oil flooded rotary compressors.

There is a wide range of availability in configuration and in pressure and capacity. Dry types deliver

oil-free air and are available in sizes up to 20,000 cfm and pressure upto 15 bar. Lubricated types are

available in sizes ranging from 100 to 1000 cfm, with discharge pressure up to 10 bar.

Dynamic Compressors

Dynamic compressors (Figure 3.5) are mainly centrifugal

compressors and operate on similar principles to centrifugal pump.

These compressors have appreciably different characteristics as

compared to reciprocating machines. A small change in

compression ratio produces a marked change in compressor output

and efficiency. Centrifugal machines are better suited for

applications requiring very high capacities, typically above 12,000

cfm.

The centrifugal air compressor is an oil free compressor by design. The oil-lubricated running gear is separated from the air by shaft

seals and atmospheric vents. The centrifugal is a continuous duty compresor,with few moving parts, and is particulary suited to high volume applications, especially where oil free air is required.

A single-stage centrifugal machine can provide the same capacity as a multi-stage reciprocating

compressor. Machines with either axial or radial flow impellers are available.

The major limitation of a centrifugal compressor is that it operates at peak efficiency at design point

only and any deviation from the operating point penalizes efficiency. When selecting centrifugal

compressors, close attention should be paid during system design to ensure that at high pressure, with

the consequent reduction in flow, the surge point or zone of unstable operation is not reached.

Axial flow compressors are suitable for higher compression ratios and are generally more efficient

than radial compressors. Air is allowed to pass through series of alternate rows of rotating blades

(attached with rotors) and fixed blades (fixed to casing), having direction of flow parallel to the axis.

The general selection criteria for compressor is given in the Table 3.1

Comparison of Different Compressors

The power consumption of various compressors depends on the operating pressure, free air delivery

and efficiency etc. The variations in power consumption during unloading/part load operation are more

significant and depend on the type of compressor and method of capacity control. The relative

efficiencies and part load power consumption of different compressors are given in Table 3.2.

In case of reciprocating machines, the unload power consumption is in the order of 25% of full load

power. While in screw compressors, the unload power consumption is marginally higher compared to

reciprocating machines.

It is preferable to use screw compressors for constant air requirement. If screw compressors have to

be installed for fluctuating loads, it is desirable to have screw compressor with variable speed drive

to further optimize unload power consumption.

Some of the plants have adopted the strategy of operating screw compressor at full load for meeting

the base-load requirement and reciprocating compressor for fluctuating load to optimize on unload

power consumption.

Compressor Performance

Capacity of a Compressor: Free Air Delivery (FAD)

Free air, as defined by CAGI (Compressed Air & Gas Institute) is air at ATMOSPHERIC conditions

at any specific location. Because the barometer and temperature may vary at different localities and

at different times, it follows that this term does not mean air under standard conditions.

Measured in CFM (Cubic feet per minute) this is the amount of compressed air converted back to the

actual inlet (free air) conditions before it was compressed. In other words, the volume of air, which is

drawn in from the atmosphere by the compressor, then compressed and delivered at a specific pressure.

Compressor Efficiency Definitions

Several different measures of compressor efficiency are commonly used: volumetric efficiency, adiabatic

efficiency, isothermal efficiency and mechanical efficiency.

Adiabatic and isothermal efficiencies are computed as the isothermal or adiabatic power divided by

the actual power consumption. The figure obtained indicates the overall efficiency of compressor and

drive motor.

Isothermal Efficiency

The calculation of isothermal power does not include power needed to overcome friction and generally

gives an efficiency that is lower than adiabatic efficiency. The reported value of efficiency is normally

the isothermal efficiency. This is an important consideration when selecting compressors based on

reported values of efficiency.

Volumetric Efficiency

For practical purposes, the most effective guide in comparing compressor efficiencies is the specific power

consumption 1.e. kW/volume flow rate, for different compressors that would provide identical duty.

Compressed Air System Components

Compressed air system consist of following major components: Intake air filters, inter-stage coolers,

after coolers, air dryers, moisture drain traps, receivers, piping network, filters, regulators and lubricators

(see Figure 3.6).

Intake Air Filters: Prevent dust from entering compressor; Dust causes sticking valves,

scoured cylinders, excessive wear etc.

Inter-stage Coolers: Reduce the temperature of the air before it enters the next stage to

reduce the work of compression and increase efficiency. They are normally water-cooled.

After Coolers: The objective is to remove the moisture in the air by reducing the temperature

in a water-cooled heat exchanger.

Air-dryers: The remaining traces of moisture after after-cooler are removed using air dryers

because air for instrument and pneumatic equipment has to be relatively free of any moisture.

The moisture is removed by using adsorbents like silica gel /activated carbon or refrigerant

dryers.

Moisture Drain Traps: Moisture drain traps are used for removal of condensate from the

compressed air. These traps resemble steam traps and various types used are manual drain

cocks, timer based / automatic drain valves etc.

Receivers: Air receivers are provided as storage and smoothening pulsating air output -

reducing pressure variations from the compressor.

Efficient Operation of Compressed Air Systems

Location of Compressors

The location of air compressors and the quality of air drawn by the compressors will have a significant

influence on the amount of energy consumed. Compressor performance as a breathing machine improves

with cool, clean, dry air at intake.

Cool air intake

As a thumb rule, “Every 4°C drop in inlet air temperature results in lower energy consumption by 1

% to achieve equivalent output”. Hence, cool air intake leads to a more efficient compression (see

Table 3.3).

Table 3.3

Since heat is generated during operation of compressors, temperature of air inside the compressor

room will be higher than the ambient temperature. Hence, it is preferable to draw cool ambient air

from outside. While extending air intake from the outside of room, care should be taken to minimize

excess pressure drop in the suction line, by selecting a large diameter duct with minimum number of

bends.

Dust Free Air Intake

Dust in the suction air causes excessive wear of moving parts and results in malfunctioning of the

valves due to abrasion. Suitable air filters should be provided at the suction side.

Air filters should

have high dust separation capacity, low-pressure drops and robust design to avoid frequent cleaning

and replacement. See Table 3.4 for effect of pressure drop across air filter on power consumption.

Air filters should be selected based on the compressor type and installed as close to the compressor as

possible. As a thumb rule “For every 250 mm WC pressure drop increase across at the suction path

due to choked filters etc, the compressor power consumption increases by about 2 percent for the same

output”

Hence, it is advisable to clean inlet air filters at regular intervals to minimize pressure drops. Manometers

or differential pressure gauges across filters may be provided for monitoring pressure drops so as to

plan filter-cleaning schedules.

Atmospheric air always contains some amount of water vapour, depending on the relative humidity,

being high in wet weather. The moisture level will also be high if air is drawn from a damp area - for

example locating compressor close to cooling tower, or dryer exhaust is to be avoided (see Table 3.5).

The moisture-carrying capacity of air increases with a rise in temperature and decreases with increase

in pressure.

Elevation

The altitude of a place has a direct impact on the volumetric efficiency of the compressor. The effect

of altitude on volumetric efficiency is given in the Table 3.6.

It is evident that compressors located at higher altitudes consume more power to achieve a particular

delivery pressure than those at sea level, as the compression ratio is higher.

Cooling Water Circuit

Most of the industrial compressors are water-cooled, wherein the heat of compression is removed by

circulating cold water to cylinder heads, inter-coolers and after-coolers. The resulting warm water is

cooled in a cooling tower and circulated back to compressors. The compressed air system performance

depends upon the effectiveness of inter-coolers, after coolers, which in turn are dependent on cooling

water flow and temperature.

Further, inadequate cooling water treatment can lead to increase, for example, in total dissolved solids

(TDS), which in turn can lead to scale formation in heat exchangers. The scales, not only act as insulators

reducing the heat transfer, but also increase the pressure drop in the cooling water pumping system.

Use of treated water or purging a portion of cooling water (blow down) periodically can maintain TDS

levels within acceptable limits. It is better to maintain the water pH by addition of chemicals, and

avoid microbial growth by addition of fungicides and algaecides.

Efficacy of Inter and After Coolers

Efficacy is an indicator of heat exchange performance- how well intercoolers and after coolers are

performing. Inter-coolers are provided between successive stages of a multi-stage compressor to reduce

the work of compression (power requirements) - by reducing the specific volume through cooling the

air - apart from moisture separation.

Ideally, the temperature of the inlet air at each stage of a multi-stage machine should be the same as

it was at the first stage. This is referred to as “perfect cooling” or isothermal compression. The cooling

may be imperfect due to reasons described in earlier sections. Hence in actual practice, the inlet air

temperatures at subsequent stages are higher than the normal levels resulting in higher power

consumption, as a larger volume is handled for the same duty (See Table 3.7).

It can be seen from the Table 3.7 that an increase of 5.5°C in the inlet air temperature to the second

stage results in a 2 % increase in the specific energy consumption. Use of water at lower temperature

reduces specific power consumption. However, very low cooling water temperature could result in

condensation of moisture in the air, which if not removed would lead to cylinder damage.

Similarly, inadequate cooling in after-coolers (due to fouling, scaling etc.), allow warm, humid air into the

receiver, which causes more condensation in air receivers and distribution lines, which in consequence,

leads to increased corrosion, pressure drops and leakages in piping and end-use equipment. Periodic cleaning

and ensuring adequate flow at proper temperature of both inter coolers and after coolers are therefore

necessary for sustaining desired performance. Typical cooling water requirement is given in Table 3.8.

Pressure Settings

Compressor operates between pressure ranges called as loading (cut-in) and unloading (cut-out)

pressures. For example, a compressor operating between pressure setting of 6 - 7 kg/cm? means that

the compressor unloads at 7 kg/cm? and loads at 6 kg/cm’. Loading and unloading is done using a

pressure switch.

For the same capacity, a compressor consumes more power at higher pressures. They should not be

operated above their optimum operating pressures as this not only wastes energy, but also leads to

excessive wear, leading to further energy wastage. The volumetric efficiency of a compressor is also

less at higher delivery pressures.

Reducing Delivery Pressure:

The possibility of lowering (optimising) the delivery pressure settings should be explored by careful

study of pressure requirements of various equipments, and the pressure drop in the line between the

compressed air generation and utilization points. Typical power savings through pressure reduction is

shown in Table 3.9.

The pressure switches must be adjusted such that the compressor cuts-in and cuts-out at optimum

levels.

A reduction in the delivery pressure by | bar in a compressor would reduce the power consumption

by 6— 10%. For example, reduction of delivery pressure by | kg/cm? (from 8 kg/cm? to 7 kg/cm?)

would result in 9% input power savings.

Compressor modulation by Optimum Pressure Settings:

Very often in an industry, different types, capacities and makes of compressors are connected to a

common distribution network. In such situations, proper selection of a right combination of compressors

and optimal modulation of different compressors can conserve energy.

When more than one compressor feeds a common header, compressors have to be operated in such a

way that the cost of compressed air generation is minimal.

« If all compressors are similar, the pressure setting can be adjusted such that only one compressor

handles the load variation, whereas the others operate more or less at full load.

« If compressors are of different sizes, the pressure switch should be set such that only the

smallest compressor is allowed to modulate (vary in flow rate).

« If different types of compressors are operated together, unload power consumptions are

significant. The compressor with lowest no load power must be modulated.

« In general, the compressor with lower part load power consumption should be modulated. «Compressors can be graded according to their specific energy consumption, at different

pressures and energy efficient ones must be made to meet most of the demand (see Table 3.10)

Compressor modulation

Assessing compressed air system study for a plant section gave following results. Comment on the

results?

«Compressors on line A, B, C, D, E (all reciprocating type)

« Trial observation Summary

Comments:

For a cycle time of 45 minutes (39.12 + 5.88)

1) Compressed air generated in m3

= 45 (13.17) + 45 (12.32) + 45 (13.14) + 45 (12.75) + 5.88 (13.65)

= 2392.36 m3

ii) Power consumption kWh

=45/60(115.3)=45/60(117.20)=45/60(108.3)=45/60(104.3)=5.88/60(109.30)=39.12/60(39.3)

=370.21 kWh/45mint.

iii)Compressed air generation actual capacity on line in m3

= 45 [13.17 + 12.32 + 13.14 + 12.75 + 13.65]

= 2926.35 m3

a)The consumption rate of the section connected

= 2392.36 / 45

= 53.16 m3/minute

b)Compressor air drawl as a % of capacity on line is

= [2392.36 / 2926.35 | x 100

= 81.75 %

c)Specific power consumption

= 370.21 / 2392.36

= 0.155 kW/m3

d)Idle power consumption due to unload operation

= 25.62 [=39.12 x 39.3 / 60] kWh in

every 45 minutes cycle i.e., 34.16 [=25.62 x 60 / 45] kWh every hour.

e) It would be favourable in short term and energy efficient to keep the compressor ‘D’

in cycling mode on account of lower un-load losses and hence capacity. Speed of the

compressor can also be reduced by reducing motor pulley size.

f) A suitable smaller capacity compressor can be planned to replace the compressor

with highest unload losses.

g) An investigation is called for, as to why such a large variation of unload power drawn,

exists although all compressors have almost the same rated capacity.

Segregating low and high pressure air requirements

If the low-pressure air requirement is considerable, it is advisable to generate low pressure and high pressure air separately, and feed to the respective sections instead of reducing the pressure through

pressure reducing valves, which invariably waste energy.

Minimum pressure drop in air lines

Pressure drop in air lines is depending upon the quantity of airflow, diameter of the pipeline, pipe

length and pipe geometry i.e. the bends in the pipe lines.-Excess pressure drop due to inadequate pipe

sizing, choked filter elements, improperly sized couplings and hoses represent energy wastage

The pipelines should be with minimum number of Joints, bends and fittings. Further to minimize

the joints, it should be ensured that joints are welded instead of flexible or screwed joints. This

facilitates minimizing the leakages and pressure drop.

Typical acceptable pressure drop in industrial practice is 0.3 bar in mains header at the farthest point

and 0.5 bar in distribution system.

The Table 3.11 illustrates the energy wastage, if the pipes are of smaller diameter.

Equivalent lengths of fittings

Not only piping, but also fitting are a source of pressure *losses. Typical pressure losses for various

fitting are given in Table 3.12.

Blowers in place of Compressed Air System

Since the compressed air system is already available, plant engineer may be tempted to use compressed

air to provide air for low-pressure applications such as agitation, pneumatic conveying or combustion

air. Using a blower that is designed for lower pressure operation will cost only a fraction of compressed

air generation energy and cost.

Capacity Control of Compressors

In many installations, the use of air is intermittent. Therefore, some means of controlling the output

flow from the compressor is necessary. The type of capacity control chosen has a direct impact on the

compressor power consumption. Some control schemes commonly used are discussed below:

Automatic On / Off Control:

Automatic On /Off control,as its name implies, starts or stops the compressor by means of a pressure

activated switch as the air demand varies. This is a very efficient method of controlling the capacity

of compressor, where the motor idle-running losses are eliminated, as it completely switches off the

motor when the set pressure is reached. This control is suitable for small compressors.

Load and Unload

This is a two-step control where compressor is loaded when there is air demand and unloaded when

there is no air demand. During unloading, a positive displacement compressor may consume up to 30

% of the full load power, depending upon the type, configuration, operation and maintenance practices.

Multi-step Control

Large capacity reciprocating compressors are usually equipped with a multi-step control. In this type

of control, unloading is accomplished in a series of steps, (0%, 25 %, 50 %, 75 % & 100 %) varying

from full load down to no-load (see Table 3.13).

The capacity of centrifugal compressors can be controlled using variable inlet guide vanes. However,

another efficient way to match compressor output to meet varying load requirements is by speed control

(see Table 3.14).

At low volumetric flow (below 40 %), vane control may result in lower power input compared to speed

control due to low efficiency of the speed control system. For loads more than 40 %, speed control is

recommended.

Avoiding Misuse of Compressed Air:

Misuse of compressed air for purposes like body cleaning, liquid agitation, floor cleaning, drying,

equipment cooling and other similar uses must be discouraged. Wherever possible, low-pressure air

from a blower should be substituted for compressed air, for example secondary air for combustion in

a boiler / furnace.

The following Table 3.15 gives an idea of savings by stopping use of compressed air by choosing

alternative methods to perform the same task.

° Electric motors can serve more efficiently than air-driven rotary devices, wherever applicable.

The Table gives the comparison of pneumatic grinders and electrical grinders.

It may be noted that in some areas use of electric tools are not permitted due to safety constraints,

especially places where inflammable vapours are present in the environment. It should always be

remembered that safety consideration always overrides energy conservation.

1. In place of pneumatic hoists, electric hoists can be used.

2. Material conveying applications by blower systems can be replaced preferably by a combination

of belt / screw conveyers and bucket elevators. In a paper manufacturing facility, compressed

air was used for conveying wood chips. The equivalent power consumption was 77 kW. This method of conveying was replaced by blower system consuming only 7 kW, a saving of 70

kW. This has also been widely applied in cement

industry where pneumatic conveying has been

replaced by bucket and screw conveyor resulting

in significant energy reduction.

3.When moving air really is required for an

application, often sources other than compressed

air can do the job. For applications like blowing

of components, use of compressed air amplifiers (see Figure 3.7), blowers or gravity-based systems may be possible. Brushes can sweep away debris from work in progress as effectively as high-pressure air. Blowers can also be used for this purpose. Many applications do not require clean, dry, high-pressure and expensive 6 bar or 7 bar compressed air rather, only moving air is needed to blow away debris, provide cooling, or

other functions. In these cases, local air fans or blowers may satisfy the need for moving air

much economically. If a 4” hose pipe is kept open at a 7 bar compressed air line for cleaning

for at least 1000 hours / annum, it can cost about Rs. 1.0 lakhs / annum. If absolutely necessary,

compressed air should be used only with blow guns to keep the air pressure below 2 bar.

4. For applications, where compressed air is indispensable for cleaning internal crevices of

machines etc., installation of a separate cleaning air header with a main isolation valve may be

considered. The main valve should be opened only for a few, well-defined time periods during

the whole day; no connections for cleaning should be provided from process or equipment air

lines.

5. Replacement of pneumatically operated air cylinders by hydraulic power packs can be

considered.

. 6.Vacuum systems are much more efficient than expensive venturi methods, which use expensive

compressed air rushing past an orifice to create a vacuum.

7 . Mechanical stirrers, conveyers, and low-pressure air will mix materials far more economically

than high-pressure compressed air.

Avoiding Air Leaks and Energy Wastage:

The major opportunity to save energy is in the prevention of leaks in the compressed air system. Leaks

frequently occur at air receivers, relief valves, pipe and hose joints, shut off valves, quick release

couplings, tools and equipment. In most cases, they are due to poor maintenance and sometimes,

improper installations etc.

Air leakages through Different Size Orifices The Table 3.16 gives the amount of free air wasted for different nozzles sizes and pressure.

Cost of Compressed Air Leakage:

It may be seen from Table 3.17 that any expenditure on stopping leaks would be paid back through

energy saving.

Steps in simple shop-floor method for leak quantification

1. Shut off compressed air operated equipments (or conduct test when no equipment is using

compressed air).

2. Run the compressor to charge the system to set pressure of operation

3. Note the sub-sequent time taken for ‘load’ and ‘unload’ cycles of the compressors. For

accuracy, take ON & OFF times for 8 — 10 cycles continuously.

4.Then calculate total ‘ON’

Time (T) and Total ‘OFF’ time (t).

. The system leakage is calculated as:

Where,

Q = Compressor capacity (m/min)

T = Time on load in minutes

t = Time on unload in minutes

EXAMPLE

In the leakage test in a process industry, following results were observed

Compressor capacity (m3/minute) = 35

Cut in pressure, kg/cm2(g) = 68

Cut out pressure, kg/cm2(g) = 75

Load kW drawn = 188kW

Unload kW drawn = 54kW

Average ‘Load’ time, T = 1.5 minutes

Average ‘Unload’ time, t = 10.5 minutes

Comment on leakage quantity and avoidable loss of power due to air leakages.

Leakage Detection by Ultrasonic Leak Detector

Leakage tests are conducted by a Leak Detector having a sensing probe, which senses when there are

leakages in compressed air systems at high temperatures-beneath insulated coverings, pipelines,

manifolds etc.

The leak is detected by ultrasonic vibration. Leak testing is done by observing and locating sources

of ultrasonic vibrations created by turbulent flow of gases passing through leaks in pressurized or

evacuated systems.

Line Moisture Separator and Traps

Although, in an ideal system, all cooling and condensing of air should be carried out before the air

leaves the receiver, this is not very often achieved in practice. The amount of condensation, which

takes place in the lines, depends on the efficiency of moisture extraction before the air leaves the

receiver and the temperature in the mains itself. In general, the air main should be given a fall of not

less than 1 m in 100 m in the direction of air flow, and the distance between drainage points should

not exceed 30m.

Drainage points should be provided using equal tees, as it assists in the separation of water. Whenever

a branch line is taken off from the mains it should leave at the top so that any water in the main does

not fall straight into the plant equipment. Further, the bottom of the falling pipe should also be drained.

Compressed Air Filter

Although, some water, oil and dirt are removed by the separators and traps in the mains, still some are

always left, which are carried over along with compressed air. Moreover, pipe systems accumulate

scale and other foreign matters, such as small pieces of gasket material, jointing compounds etc. Burnt

compressor oil may also be carried over in pipe work, and this, with other contaminants, forms a

gummy substance. To remove these, all of which are liable to have harmful effects on pneumatic

equipment, the air should be filtered as near as possible to the point of use. Water and oil collected in

the filter sump must be drained off; because if the level is allowed to build up, it is forced through the

filter element into the very system for which it is designed to protect.

Regulators

In many instances, pneumatic operations are to be carried out at a lower pressure than that of the main

supply. For these applications, pressure regulators are required to reduce the pressure to the required

value and also to ensure that it remains reasonably constant at the usage point.

Lubricators

Where air is used to drive prime movers, cylinders and valves, they should be fitted with a lubricator.

Essentially, a lubricator is a reservoir of oil and has been designed so that when air is flowing, a metered

amount of oil is fed in mist form into the air stream. This oil is carried with the motive air, to the point

of use to lubricate all moving parts. All lubricators require a certain minimum rate of airflow to induce

oil into their stream. It is advisable to install filters, regulators and lubricators as close as possible to

the equipment being served.

Air Dryers

The atmospheric air has certain amount of moisture. The moisture holding capacity of air depends

on the ambient temperature. Higher the temperature more is the moisture holding capacity of air

in the form of water vapour and vice versa. Saturated air at a given temperature is the air that contains

the maximum amount of water in the form of water vapour. Any excess water vapour will be condensed

in the form of water.

About 60 to 75% of moisture in compressed air is removed at the after cooler. This is sufficient for

many plant air applications such as cleaning, atomisation etc. As compressed air leaves the after cooler

and passes through the compressed air lines, the temperature of the compressed air further reduces.

The remaining water vapour in the air starts condensing.

The effects of water particles in the compressed air are given below.

. The water particles travel at the same velocity of compressed air and damages the pneumatic

valves or instruments at the user ends by erosion.

. Corrosion in the distribution pipe work.

. Impaired finishing processes particularly in paint spraying, sheet cleaning etc.

Hence, the water vapour from the compressed air has to be removed, for applications such as

instrumentation and pneumatics. This can be achieved by passing the compressed air through the air

dryers.

The extent of drying compressed air is expressed by the term “Atmospheric Dew Point” which is

the temperature at which moisture present in the air starts condensing at atmospheric pressure. Lower

the dew point, more dry is the air. Air at -40°C atmospheric dew point means no moisture would

condense unless temperature of the air is reduced to less than — 40°C, at atmospheric pressure.

The moisture content corresponding to various atmospheric dew points is shown in the table 3.18

below:

The performance of a dryer is quoted in terms of “pressure dew point’ and there is a relation between

both dew points.

Increasing the pressure of a gas increases the dew point temperature of the gas. For example, air at

atmospheric pressure of 1013.3 mbar has a dew point temperature of -10 °C. Corresponding partial

pressure of water vapour is 2.8 mbar. If this air is compressed and the total pressure is doubled to

2026.6 mbar, then according to Dalton’s law, the partial pressure of water vapour is also doubled to

the value of 5.6 mbar. The dew point temperature corresponding to 5.6 mbar is approximately -1 °C,

so it is clear that increasing the pressure of the air also increases the dew point temperature of the air.

Most commonly used dryers in the industry are:

1. Refrigerant type and

2. Adsorption type - can be of the following type:

(a) Blower reactivated type

(b) Heatless purge type

(c) Heat of compression (HOC) type

The principle of operation of different dryers are explained as follows.

Refrigerant Dyers

The system (Figure 3.8) is straight mechanical refrigeration in which the dew point of air is reduced by chilling.Additionally, a second heat exchanger is introduced wherein the outgoing cold air pre-cools the incoming compressed air. The compressed air leaves the system fully dry. The achievable dew point (atmospheric) in this kind of refrigerant dryer is -20°C.

Features:

1.Refrigeration drying is the most economical process of approximately 90 % of all applications.

2.Almost 100 % of all solid particles and water droplets larger than 3 um are separated.

3.The pressure loss from the dryer is approximately 0.2 bar.

Adsorption Drying

Drying compressed air by adsorption is a purely physical process. The moisture is bound to the drying

agent by force of adhesion (unbalanced molecular attraction). The moisture stays on the inner and

outer surfaces of the adsorption material without a chemical reaction taking place. The adsorption

material has an open porous structure and a large inner surface. The most common adsorption materials

used for compressed air drying are activated alumina and silica gel.

Operating principle

During the drying process the moist compressed air flows through an adsorption tank. The moisture is bound, which dries the compressed air. This process generates heat. The adsorption material must be regenerated when the adhesive forces are balanced by water deposits. This means that the water must be removed from the adsorption material. For this reason there must be second parallel drying tank to maintain continual operation. The active tank A (Figure 3.9) dries the compressed air, while the inactive tank B regenerates without pressure. Based on the method of regeneration the adsorption dryers can be classified as follows,

Blower Reactivated Type Dryer

blower and external heater is used to achieve the regenerating temperature. The operating cost is higher because of the heater (electrical or steam) and also because there is a purge loss of about 1-2% of dry compressed air. The vessel which is regenerated is purged with dry air before it is taken into service. These dryers are normally used for capacities higher than 250 cfm. The schematic of the dryer is shown in Figure 3.10. Vessel ‘A’ is in service and vessel *B’ is in heating mode. Cooling is done after which vessel ‘B’ is taken into service and vessel ‘A’ goes into regeneration mode.

Heatless Purge Type Dryer

The operation is very similar to the blower reactivated type, only difference being that no heating of

the dessicant is done. Pure dry compressed air is used for purging through the saturated dessicant.

These are used for capacities less than 250 cfm. The operating cost is very high due to purge losses of

about 12-15%. The schematic of the dryer is shown in Figure 3.11.

Heat of Compression (HOC) Dryer

This is a break-through in drying technology where the operating cost is zero or very minimal. HOC dryers are available from 400 cfm to 5000 cfm capacity. Compressed air, directly from compressor discharge (before after cooler), which is at a temperature of 135°C (in the case of reciprocating compressor) is used to regenerate the dessicant. There are no electrical heaters and no purging loss. This makes the dryer very attractive in terms of operating cost.

The dryer consists of two vessels - ‘A’ and ‘B’. Vessel ‘A’ will be in service for 4 hours. Meanwhile vessel ‘B’ is reactivated which consists of heating for 2 1/2 hrs and cooling for 1 1/2 hrs. After this, vessel ‘B’ is taken into service and vessel ‘A’ is reactivated. The regeneration cycle consisting of heating and cooling cycle as explained as follows

a. Vessel ‘A’in service, vessel ‘B’in heating

Air from compressor enters 4-way valves V2 and V1 (Figure 3.12 (a)) and directly to vessel ‘B’ so as to start the heating process. From vessel ‘B’ the air through valve V3 and V2 enters after cooler AC1, where it loses some of the moisture. Through V3 again air enters vessel 'A’where moisture is adsorbed by the dessicant and finally leaves through V1 to an After-cooler AC2 where it is A cooled to about 35-40 °C. After getting filtered in the After-filter, air goes to process which is dry to an atmospheric dew point of -40 °C. The heating cycle is normally for 2 1/2 hours duration.:

b. Vessel ‘A’ in service, vessel ‘B’in cooling Air from compressor passes through V2 (Figure 3.12 (b)), gets cooled in AC1 and enters vessel ‘B’ through V3. After cooling the dessicant in vessel ‘B’ air passes through 4-way valves V1, V2 and V3 and enters vessel “A’, which is in service. The air on getting dry, enters After-cooler AC2 via V1, gets cooled to about 35-40°C. This air dryed to an atmospheric dew point of -40°C is now ready for use. The cooling cycle is normally for about 11/2 hour duration.

Membrane Dryers

Membrane dryers use the process of selective permeation of the gas components in the air. The dryer

is a cylinder which houses thousands of tiny hollow polymer fibers with an inner coating. These fibers

have selective permeation for the removal of water vapor. As filtered, wet compressed air enters the

cylinder, the membrane coating allows water vapor to permeate the membrane wall and collect between

the fibers, while the dry air continues through the fibers in the cylinder at almost the same pressure as

the incoming wet air. The permeated water is vented to the atmosphere outside of the cylinder.

The permeation or separation is caused by the difference in the partial pressure of a gas between the

inside and the outside of the hollow fiber.

Membrane dryers (Figure 3.13) are simple to operate, silent while operating, have no moving parts,

low power consumption and minimal service requirements (mainly filters upstream of the dryer).

Refer Table 3.19 for typical dew point and power consumption data for dryers.

Air Receivers

The air receiver dampens pulsations entering the discharge from the compressor, serves as a reservoir

for sudden or unusually heavy demands in excess of compressor capacity, prevents too frequent loading

and unloading (short cycling) of the compressor and separates moisture and oil vapour, allowing the

moisture carried over from the after coolers to precipitate.

The air receiver should be generously sized to give a large cooling surface and even out the pulsation

in delivered air pressure from reciprocating compressor. As per IS 7938 — 1976, volume of the air

receiver (in/m3) should be 1/10" to 1/6" of output in m3/min. Providing an air receiver near the load

end, where there is sudden high demand lasting for a short period, would avoid the need to provide

extra compressor capacity.

Sizing of compressed air piping

The compressed air piping is sized based on the allowable velocity of compressed air in the pipeline,

keeping a check on the pressure drop. In compressed air line if the pressure drop is high, the

operating pressure at the generation end has to be increased to match with the requirement. This will

result in increased power consumption of the compressor.

Velocities between 6 to 10 m/sec are usual in compressed air mains. This velocity range is sufficiently

low to prevent excessive pressure drops on most systems and also will allow moisture to precipitate.

The volume of air changes if any of the following changes.

¢ Operating Pressure

¢ Temperature

¢ Both Pressure and Temperature

The law dealing with the expansion of air wherein pressure and temperature are changing together is

given below.

P1*V1/T1 = P2*V2T2

Where P1 V1 and T1 are the original pressure, volume and temperature and P2 V2 and T2 are the

new pressure, volume and temperature respectively.

The following procedure can be adopted for estimating the size of a compressed air line.

Loss of air pressure due to friction

The loss of pressure in piping is caused by resistance in pipe fittings and valves, which dissipates

energy by producing turbulence. The piping system will be designed for a maximum allowable pressure

drop of 5 percent from the compressor to the most distant point of use.

Piping layout

Where possible the piping system should be arranged as a closed loop or “ring main” to allow for more

uniform air distribution to consumption points and to equalize pressure in the piping. Separate services

requiring heavy air consumption and at long distances from the compressor unit should be supplied by separate main airlines. Pipes are to be installed parallel with the lines of the building, with main and branch headers sloping down toward a dead end. Traps will be installed in airlines at all low points and dead ends to remove condensed moisture. Automatic moisture traps used for this purpose are effective only when the air has been cooled and the moisture has precipitated. Branch headers from compressed air mains will be taken off at the top to avoid picking up moisture.

Capacity Utilisation

In many installations, the use of air is intermittent. This means the compressor will be operated on

low load or no load condition, which increases the specific power consumption per unit of air generated.

Hence, for optimum energy consumption, a proper compressor capacity control should be selected. The nature of the control device depends on the function to be regulated. One of the objectives of a good compressed air management system would be to minimize unloading to the least as unloading consumes up to 30% of full load power.

One way of doing this is to use a smaller compressor.

Decentralized compressors, as against centralized compressors often serve this purpose better by

having the option to switch off when air is not need in a particular section/equipment. If a compressor is oversized and operates at unloading mode for long periods, an economical way will be to suitably change the pulley size of the motor or compressor and reduce the RPM to de-rate the compressor to a lower capacity.

With decreasing cost of variable speed drives, it has become a viable option to maintain constant

pressure in the system and to avoid unloading operations by varying the speed of the compressor.

However, caution should be taken for operations at very low speeds, since it will affect the lubricating

system. This can be overcome by providing a separate lube oil system independent of the compressor.

Compressor Capacity Assessment

Due to ageing of the compressors and inherent inefficiencies in the internal components, the free air delivered may be less than the design value, despite good maintenance practices. Sometimes, other factors such as poor maintenance, fouled heat exchanger and effects of altitude also tend to reduce free air delivery. In order to meet the air demand, the inefficient compressor may have to run for more time, thus consuming more power than actually required.

The power wastage depends on the percentage deviation of FAD capacity. For example, a worn out compressor valve can reduce the compressor capacity by as much as 20 percent. A periodic assessment

of the FAD capacity of each compressor has to be carried out to check its actual capacity. If the deviations are more than 10 %, corrective measures should be taken to rectify the same. The ideal method of compressor capacity assessment is through a nozzle test wherein a calibrated nozzle is used as a load, to vent out the generated compressed air. Flow is assessed, based on the air temperature, stabilization pressure, orifice constant etc.

Simple method of Capacity Assessment in Shop floor

Isolate the compressor along with its individual receiver being taken for test from main compressed

air system by tightly closing the isolation valve or blanking it, thus closing the receiver outlet.

Open water drain valve and drain out water fully and empty the receiver and the pipe line. Make sure

that water trap line is tightly closed once again to start the test. Start the compressor and activate the

stopwatch. Note the time taken to attain the normal operational pressure P2 (in the receiver) from initial

pressure P1

Calculate the capacity as per the formulae given below:

Actual Free air discharge

The above equation is relevant where the compressed air temperature is same as the ambient air

temperature, i.e., perfect isothermal compression. In case the actual compressed air temperature at

discharge, say t2°C is higher than ambient air temperature say t1°C (as is usual case), the FAD is to be

corrected by a factor (273 + t1) / (273 +t2).

EXAMPLE 1

An instrument air compressor capacity test gave the following results (assume the final compressed

air temperature is same as the ambient temperature) - Comment?

Piston displacement : 16.88 m3/minute

Theoretical compressor capacity : 14.75 m3/minute @ 7 kg/cm2

Compressor rated rpm 750 : Motor rated rpm : 1445

Receiver Volume : 7.79 m3

Additional hold up volume,

1.e., pipe / water cooler, etc., is : 0.4974 m3

Total volume : 7.79+0.4974 =8.287 m3

Initial pressure P1 : 0.5 kg/cm2

Final pressure P,, : 7.03 kg/cm2

Atmospheric pressure P0 : 1.026 kgf/cm’A

Time taken to build up pressure : 4.021 minutes

Capacity shortfall with respect to 14.75 m3/minute rating is 1.63 m3/minute i.e., 11.05 %, which indicates compressor performance needs to be investigated further.

Checklist for Energy Efficiency in Compressed Air System1.Ensure air intake to compressor is not warm and humid by locating compressors in

well-ventilated area or by drawing cold air from outside. Every 4°C rise in air inlet

temperature will increase power consumption by percent.

2.Clean air-inlet filters regularly. Compressor efficiency will be reduced by 2 percent for

every 250 mm WC pressure drop across the filter.

3.Keep compressor valves in good condition by removing and inspecting once every six

months. Worn-out valves can reduce compressor efficiency by as much as 50 percent.

4.Install manometers across the filter and monitor the pressure drop as a guide to

replacement of element.

5.Minimize low-load compressor operation; if air demand is less than 50 percent of

compressor capacity, consider change over to a smaller compressor or reduce compressor

speed appropriately (by reducing motor pulley size) in case of belt driven compressors.

6.Consider the use of regenerative air dryers, which uses the heat of compressed air to

remove moisture.

7.Fouled inter-coolers reduce compressor efficiency and cause more water condensation

in air receivers and distribution lines resulting in increased corrosion. Periodic cleaning

of inter-coolers must be ensured.

8.Compressor free air delivery test (FAD) must be done periodically to check the present

operating capacity against its design capacity and corrective steps must be taken if

required.

9.If more than one compressor is feeding to a common header, compressors must be

operated in such a way that only one small compressor should handle the load variations

whereas other compressors will operate at full load.

10.The possibility of heat recovery from hot compressed air to generate hot air or water for

process application must be economically analyzed in case of large compressors.

11.Consideration should be given to two-stage or multistage compressor as it consumes less

power for the same air output than a single stage compressor.

12.If pressure requirements for processes are widely different (e.g. 3 bar to 7 bar), it is

advisable to have two separate compressed air systems.

13.Reduce compressor delivery pressure, wherever possible, to save energy.

14.Provide extra air receivers at points of high cyclic-air demand which permits operation

without extra compressor capacity.

15Retrofit with variable speed drives in big compressors, say over 100 kW, to eliminate the

‘unloaded’ running condition altogether.

16. Keep the minimum possible range between load and unload pressure settings.

17. Automatic timer controlled drain traps wastes compressed air every time the valve

opens. So frequency of drainage should be optimized.

18. Check air compressor logs regularly for abnormal readings, especially motor current

cooling water flow and temperature, inter-stage and discharge pressures and temperatures

and compressor load-cycle.

19. Compressed air leakage of 40- 50 percent is not uncommon. Carry out periodic leak tests

to estimate the quantity of leakage.

20. Install equipment interlocked solenoid cut-off valves in the air system so that air supply

to a machine can be switched off when not in use.

21. Present energy prices justify liberal designs of pipeline sizes to reduce pressure drops.

22. Compressed air piping layout should be made preferably as a ring main to provide

desired pressures for all users.

23. A smaller dedicated compressor can be installed at load point, located far off from the

central compressor house, instead of supplying air through lengthy pipelines.

24. All pneumatic equipment should be properly lubricated, which will reduce friction,

prevent wear of seals and other rubber parts thus preventing energy wastage due to

excessive air consumption or leakage.

25. Misuse of compressed air such as for body cleaning, agitation, general floor cleaning,

and other similar applications must be discouraged in order to save compressed air and

energy.

" Pneumatic equipment should not be operated above the recommended operating pressure

as this not only wastes energy but can also lead to excessive wear of equipment’s

components which leads to further energy wastage.

26. Pneumatic transport can be replaced by mechanical system as the former consumed about

8 times more energy. Highest possibility of energy savings is by reducing compressed

air use.

27. Pneumatic tools such as drill and grinders consume about 20 times more energy than

motor driven tools. Hence they have to be used efficiently. Wherever possible, they

should be replaced with electrically operated tools.

28. Where possible welding is a good practice and should be preferred over threaded

connections.

29. On account of high pressure drop, ball or plug or gate valves are preferable over globe

valves in compressed air lines.

Solved Example:

a) In an automobile industry a pump-up test was conducted to determine the free air delivery (FAD)

of a reciprocating compressor and the following data were obtained:

Receiver capacity and additional holdup volume

in piping and after-cooler : 4100 litres

Initial pressure : 1 kg/cm2 (g)

Final pressure : 8.5 kg/cm2 (g)

Atmospheric Pressure : 1.026 kg/cm2 (a)

Ambient air temperature : 32°C

Final compressed air temperature : 52 °C

Compressor pump up time : 65 secs

Calculate the FAD of the compressor in cubic foot per minute.

b) Further a leakage test was carried out in the same compressed air system and with the same compressor

as in problem a) above and following were the observations:

- Compressor was on load for 03 minutes

- Compressor was unloaded for 13 minutes

- Compressor was drawing 145 kW during load

Calculate the following:

i. % leakage in compressed air system

li. Leakage quantity

iii. Specific power consumption

iv. Power lost due to leakage

----------------------------------

Comments

Post a Comment