ENERGY_EFFICIENCY_IN_ELECTRICAL_UTILITIES

(Chapter 8:Lightening System)

Introduction

Most natural light comes from the sun, including moon light. Its origin makes it completely clean and

it consumes no natural resources. But man-made sources generally require consumption of resources,

such as fossil fuels, to convert stored energy into light energy.

Light is usually described as the type of electromagnetic radiation that has a wavelength visible to the

human eye, roughly 400 to 700 nanometers. Light exists as tiny “packets” called photons and exhibits

the properties of both particles and waves. Visible light, as can be seen on the electromagnetic spectrum,

as given in Figure 8.1, represents a narrow band between ultraviolet light (UV) and infrared energy

(heat). These light waves are capable of exciting the eye’s retina, which results in a visual sensation

called sight. Therefore, seeing requires a functioning eye and visible light.

The lumen (lm) is the photometric equivalent of the Watt, weighted to match the eye response of the

“standard observer”. Yellowish-green light receives the greatest weight because it stimulates the eye

more than blue or red light of equal radiometric power:

1 Watt = 683 lumens at 555 nm wavelength

The best eye sensitivity, as seen from Figure 8.2 is at 555 nm wavelength having greenish yellow

colour with a luminous efficacy of 683 lm/Watt.

Three primary considerations to ensure energy efficiency in lighting systems are:

1. Selection of the most efficient light source possible in order to minimize electricity

consumption and cost.

ii. Matching the proper lamp type to the intended work task or aesthetic application, consistent

with color, brightness control and other requirements.

iii. Establishing adequate light levels without compromising productivity improve security and

increase safety.

Basic Parameters and Terms in Lighting System

Luminous flux: The luminous flux describes the quantity of light emitted by a

light source. It is a measure of a lamp’s economic efficiency.

The most common measurement or unit of luminous flux is the lumen (Im).

The lumen rating of a lamp is a measure of the total light output of the lamp. Light

sources are labeled with an output rating in lumens.

Illuminance (E): is the quotient of the luminous flux incident on an element of

the surface at a point of surface containing the point, by the area of that element.

The lighting level produced by a lighting installation is usually qualified by the

illuminance produced on a specified plane. In most cases, this plane is the major

plane of the tasks carried out in the interior and is commonly called the working

plane. The illuminance provided by an installation affects both the performance of the tasks and the

appearance of the space. Lux (Ix) is the metric unit of measure for illuminance of a surface. One lux

is equal to one lumen per square meter. I!luminance decreases by the square of the distance (inverse

square law).

The inverse square law defines the relationship between the illuminance from a point source and

distance. It states that the intensity of light per unit area is inversely proportional to the square of the

distance from the source (essentially the radius).

Where, E = Illuminance in lux (Im/m2), I = Luminous flux in lumen (Im) and d = distance in m

An alternate form of this equation which is sometimes more convenient is:

Distance is measured from the test point to the first luminating surface - the filament of a clear bulb

or the glass envelope of a frosted bulb.

Example:

The illuminance is 10 lm/m2 from a lamp at 1 meter distance. What will be the illuminance at half the

distance?

Average maintained illuminance: is the average of illuminance (lux) levels measured at various

points in a defined area.

Circuit Watts: is the total power drawn by lamps and ballasts in a lighting circuit under assessment.

Luminous Efficacy (Im/W);: is the ratio of luminous flux emitted by a lamp to the power consumed

by the lamp. It is a reflection of efficiency of energy conversion from electricity to light form. Unit:

lumens per lamp Watt (Im/W).

Lamp Circuit Efficacy: is the amount of light (lumens) emitted by a lamp for each Watt of power

consumed by the lamp circuit, i.e. including control gear losses. This is a more meaningful measure

for those lamps that require control gear. Unit: lumens per circuit Watt (Im/W).

Installed Load Efficacy: is the average maintained illuminance provided on a horizontal working

plane per circuit watt with general lighting of an interior. Unit: lux per Watt per square metre

(lux/W/m/2).

Installed Power Density: The installed power density per 100 lux is the power needed per square

metre of floor area to achieve 100 lux of average maintained illuminance on a horizontal working

plane with general lighting of an interior. Unit: Watts per square metre per 100 lux (W/m7/100 lux)

Color rendering index (CRI): is a measure of the effect of light on the perceived color of objects.

To determine the CRI of a lamp, the color appearances of a set of standard color chips are measured

with special equipment under a reference light source with the same correlated color temperature as

the lamp being evaluated. If the lamp renders the color of the chips identical to the reference light

source, its CRI is 100. If the color rendering differs from the reference light source, the CRI is less

than 100. A low CRI indicates that some colors may appear unnatural when illuminated by the lamp.

Luminaire: is a device that distributes filters or transforms the light emitted from one or more lamps.

The luminaire includes all the parts necessary for fixing and protecting the lamps, except the lamps

themselves. In some cases, luminaires also include the necessary circuit auxiliaries, together with the

means for connecting them to the electric supply. The basic physical principles used in optical luminaire

are reflection, absorption, transmission and refraction.

Control gear: The gears used in the lighting equipment are as follows:

¢ Ballast is a current limiting device, to counter negative resistance characteristics of any

discharge lamps. In case of fluorescent lamps, it aids the initial voltage build-up, required

for starting. In an electric circuit the ballast acts as a stabilizer. Fluorescent lamp is basically

an electric discharge lamp with two electrodes separated inside a tube with no apparent

connection between them. When sufficient voltage is impressed on these electrodes, electrons

are driven from one electrode and attracted to the other. The current flow takes place through

an atmosphere of low-pressure mercury vapour.

¢ Since the fluorescent lamps cannot produce light by direct connection to the power source,

they need an ancillary circuit and device to get started and remain illuminated. The auxiliary

circuit housed in a casing is known as ballast.

¢ Ignitors are used for starting high intensity discharge lamps such as metal halide and sodium

vapour lamps. Ignitors generate a high voltage pulse or a series of pulses to initiate the

discharge.

Light Source and Lamp Types

Lamp is equipment, which produces light. Light is that part of the electromagnetic spectrum that is

perceived by our eyes. A number of light sources are available, each with its own unique combination

of operating characteristics viz., efficacy, colour, lamp life, and the percent of output that a lamp loses

over its life.

Based on the construction and operating characteristics, the lamps can be categorized into three groups:

incandescent, fluorescent and high intensity discharge (HID) lamps. HID lamps can be further classified

as sodium vapour, mercury vapour and metal halide lamps. The most commonly used lamps are

described briefly as follows:

1) Incandescent lamp

The principal parts of an incandescent lamp also known as GLS lamp (General Lighting Service lamp)

include the filament, the bulb, the fill gas or vacuum and the cap. Incandescent lamps (Figure 8.3 A&B)

produce light by means of a wire or filament heated to incandescence by the flow of electric current through it. The filament is enclosed in an evacuated glass bulb filled with inert gas such as argon,

krypton, or nitrogen that helps to increase the brilliance of lamp and to prevent the filament from

burning out.

Reflector lamps: Reflector lamps are basically incandescent, provided with a high quality internal

mirror, which follows exactly the parabolic shape of the lamp. The reflector is resistant to corrosion,

thus making the lamp maintenance free and output efficient.

2) Halogen lamp

It has a tungsten filament and the bulb filled with halogen

gas (Figure 8.4). Current flows through the filament and

heats it up, as in incandescent lamps. These lamps

therefore generate a relatively large amount of heat. The

use of halogen increases the efficiency and extends the

service life compared with traditional incandescent

lamps. Low-voltage types are very small and are ideal

for precise direction of light, but they require a

transformer.

Tungsten atoms evaporate from the hot filament and

move toward the cooler wall of the bulb. Tungsten,

oxygen and halogen atoms combine at the bulb-wall to

form tungsten oxyhalide molecules. The bulb-wall

temperature keeps the tungsten oxyhalide molecules in

a vapor. The molecules move toward the hot filament

where the higher temperature breaks them apart.

Tungsten atoms are re-deposited on the cooler regions of the filament - not in the exact places from

which they evaporated. Breaks usually occur near the connections between the tungsten filament and

its molybdenum lead-in wires where the temperature drops sharply.

3) Fluorescent tube lamp (FTL)

It works by the fluorescence principle. A fluorescent lamp (Figure 8.5 A&B) is a glass tube containing

a small trace of a gas such as mercury vapor (for a white color), carbon dioxide (for green), neon (for

red color), etc., with a special fluorescent / phosphorescent coating on the interior surface of the tube.

It contains two filaments, one at each end of the tube and when the electrical supply is switched ON,

the contacts of the starter open and the filaments glow to heat up the gas contained inside the tube.

This action provides a voltage across its electrodes that set off an electric (gaseous mercury) arc

discharge in the tube. This generates invisible UV radiation that is high enough to ionise the warmed�up gas inside the tube. This ionised gas also called as “plasma”, excites the fluorescent coating so that

it gives out visible light. Ballast is needed to start and operate fluorescent lamps, because of the

characteristics of a gaseous arc. The luminous flux is highly dependent on the ambient temperature.

Fluorescent Lamps are about 3 to 5 times as efficient as standard incandescent lamps and can last about

10 to 20 times longer.

The different types of fluorescent lamps and their reference are given below:

Linear tubes

¢ T12-38 mm (1.5’diameter)

¢ T8-25 mm (1”diameter)

¢ T5 - 16mm (5/8”diameter)

¢ T2-6mm (1/4’’ diameter)

U-bent tubes

¢ T12-38 mm (1.5”diameter)

¢ T8-25 mm (1” diameter)

Circular tubes

¢ T9-38 mm (1.5’diameter)

¢T5 - 16 mm (5/8”diameter)

These four lamps vary in diameter (ranging from 1.5 inches that is 12/8 of an inch for T12 to 0.625 or

5/8 of an inch in diameter for TS lamps). Efficacy is another area that distinguishes one from another.

T5 & T8 lamps offer a 5-percent increase in efficacy over 40-watt T12 lamps, and have become the

most popular choice for new installations.

4) Compact fluorescent lamp (CFL)

Compact Fluorescent lamps (Figure 8.6) are compact /

miniature versions of the linear or circular fluorescent

lamps and operate in a very similar way. The luminous flux

depends on temperature. CFL’s use less power and have a

longer rated life compared to an incandescent lamp.

They are designed to replace an incandescent lamp and can fit into most existing light fixtures formerly

used for incandescent. CFL’s are available in screw type/ pin type which fit into standard sockets, and

gives off light that is similar to common fluorescent lamps.

5) Sodium vapour lamp

Low pressure sodium vapour lamp

Although low pressure sodium vapour (LPSV)

lamps (Figure 8.7) are similar to fluorescent

systems (because they are low pressure systems),

they are commonly included in the HID family.

LPSV lamps are the most efficacious light sources, but they produce the poorest quality

light of all the lamp types. Being a monochromatic light source, all colours appear black, white, or

shades of gray under an LPSV source. LPSV lamps are available in wattages ranging from 18-180.

LPSV lamp use has been generally limited to outdoor applications such as security or street lighting

and indoor, low-wattage applications where color quality is not important (e.g. stairwells). However,

because the color rendition is so poor, many municipalities do not allow them for roadway lighting.

High pressure sodium vapour lamp

The high pressure sodium vapour (HPSV)

lamp (Figure 8.8 A&B) is widely used for outdoor and industrial applications as the light is yellowish. Its higher efficacy makes it a

better choice than metal halide for these applications, especially when good color

rendering is not a priority. HPSV lamps differ

from mercury and metal-halide lamps in that

they do not contain starting electrodes; the

ballast circuit includes a high-voltage

electronic starter. The arc tube is made of a ceramic material, which can withstand temperatures up to

1300 °C. It is filled with xenon to help start the arc, as well as a sodium-mercury gas mixture.

6) Mercury vapour lamp

In a mercury vapour lamp (Figure 8.9) electromagnetic radiation is created from discharge within

mercury vapour, but the regime is different than that found in the normal fluorescent lamp. During

operation, the pressure within the lamp is in the range of 200 — 400 kPa (compared with only 1 Pa).

It is not possible to achieve the mercury vapour discharge in a cold lamp. For this reason, the lamp

also includes argon, and the initial arc is struck as an argon arc. The energy from this discharge

vapourises the mercury to get the main discharge going.

The mercury vapour lamp produces a much greater proportion of visible light than fluorescent lamp

and gives off a bluish white light. Phosphor coating can be given to improve the colour rendering index.

7) Metal halide lamp:

Metal halide lamp (Figure 8.10 A&B) can

be considered as a variant of high pressure

mercury vapour lamp (HPMYV). In addition

to mercury vapour and argon, this lamp

contains metal halide. The halides can be

a mixture of rare earth halides, usually

iodides or a mixture of sodium and

scandium iodide. The mercury vapour

radiation is augmented by that of the metals.

A highly compact electric arc is produced

in a discharge tube. A starter is needed to

switch on the lamp. The use of ceramic discharge tubes further improves the lamp

properties. The halides act in a similar manner to the tungsten halogen cycle. As the temperature

increases there is disassociation of the halide compound releasing the metal into the arc. The halides

prevent the quartz wall getting attacked by the alkali metals. By adding other metals to the mercury different spectrum can be emitted. Some lamps use a third electrode for starting, but others, especially

the smaller display lamps, require a high voltage ignition pulse.

Metal halide lamps have a significantly better colour rendering index than mercury vapour and can be

tailored by the choice of halides.

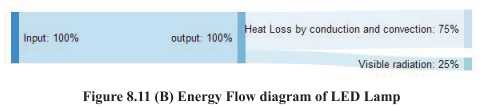

8) Light emitting diode (LED) lamp

LEDs produce light in a very unique way; they produce light via a process called electro-luminescence

(Figure 8.11), a process that starts by turning a semiconductor material into a conducting material. A

semiconductor with extra electrons is called N-type (negative) material, since it has extra negatively�charged electrons. In N-type material, free electrons can move from a negatively-charged area to a

positively charged area. A semiconductor with extra holes is called P-type (positive) material since it

has extra positively-charged gaps called holes. When excited with current the negative electron leaves

its atom and the P-type material’s positive attraction draws the free negative electron into its hole, and

the hole also moves toward the electron, so on and so forth.

As an electron travels to a hole, it carries energy, but in order to fit into the hole it must release any

extra energy, and when it does, the extra energy is released in the form of light. When we maintain a

steady flow of electrical current to the diode, it continues the process of allowing electrons to flow

from the negative charged material and fall into the positive charged holes which maintains a steady

stream of light out of the LED. The actual LED is quite small in size, usually less than one square

millimeter. Additional optical components are added to shape and direct the light. LED’s are made of

number of inorganic semiconductor materials, many of which produce different colour of light.

The efficiency of LED’s has now risen sharply and is currently up to 200 lumens per watt in the

laboratory and in some products available on the market (although more typical LED’s average output

varies from 50 to 130 lumens per watt).

Because of the low power requirement for LED’s, using solar panels becomes more practical and less

expensive than running an electrical wire or using a generator. Hence LED with battery backup for

remote application is very economical.

They do not radiate light in 360 degrees as an incandescent

does. The light will be bright wherever it is focused.

Unlike incandescent and fluorescent lamps, LEDs are not inherently white light sources. Instead, LEDs

emit nearly monochromatic light, making them highly efficient for colored light applications such as

traffic lights and exit signs.

However, to be used as a general light source, white light is needed. White

light can be achieved with LEDs in three ways:

Phosphor conversion, in which a phosphor is used on or near the LED to convert the colored light to

white light; RGB systems, in which light from multiple monochromatic LEDs (red, green, and blue)

is mixed, resulting in white light; and a hybrid method, which uses both phosphor-converted and

monochromatic LEDs.

Advantages of LED technology is as follows Low power consumption, Directional light output, High

efficiency level, Long life: upto ~100,000 hour life if junction temperature can be controlled, Instant

switching on with no warm up time, High resistance to switching cycles, High impact and vibration

resistance, No UV or IR radiation, Color control ability, allows dimming and Mercury free

LED’s also offer a number of promising environmental benefits, and they are often viewed as the future

of green lighting.

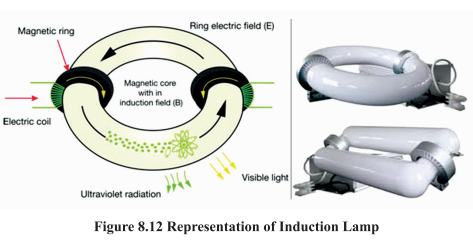

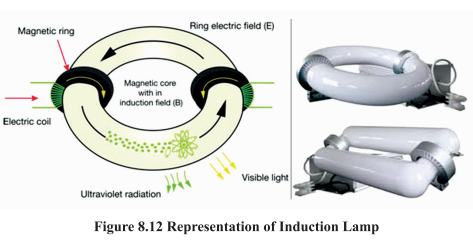

9) Induction lamp

Induction lamp is noted for ‘crisp white light output’. Uses a magnetic field to excite gases — has no

lamp parts to wear out. It consists of two main components: ballast and a sealed gas-filled bulb. Light

is produced via electromagnetic induction, without an electrode or any electrical connection inside the

bulb. Instead, high frequency electromagnetic fields are induced from outside the sealed chamber.

To produce light, the ballast supplies the electric coils with high frequency electrical current. The

ferrite magnets on either side of the bulb then emit electromagnetic fields which excite electrons within

the bulb.

As the electrons accelerate inside the bulb, they collide with mercury atoms and produce ultraviolet

(UV) light radiation. The UV light then causes the special phosphor coating inside the glass to react

in a way that produces fluorescent light within the visible spectrum. The light produced by Induction

Lighting (Figure 8.12) achieves good Color Rendering Index (CRI), with a Correlated Color

Temperature.

Advantages of Induction lamps is as follows long burning hours, very less maintenance required,

instant on/ instant re-strike and energy efficient lighting.

Recommended Illuminance Levels for Various Tasks / Activities / Locations

Recommendations on Illuminance

Scale of

Tiluminance:

The minimum illuminance for all non-working interiors, has been mentioned as 20

Lux (as per IS 3646). A factor of approximately 1.5 represents the smallest significant

difference in subjective effect of illuminance. Therefore, the following scale of

illuminances is recommended.

20—30—50—75—100—150—200-—300—500—750—1000—1500—2000, ...

Illuminance ranges:

Lux

Because circumstances may be significantly different for different interiors used

for the same application or for different conditions for the same kind of activity, a

range of illuminances is recommended for each type of interior or activity intended

of a single value of illuminance. Each range consists of three successive steps of

the recommended scale of illuminances. For working interiors the middle value (R)

of each range represents the recommended service illuminance that would be used

unless one or more of the factors mentioned below apply.

The higher value (H) of the range should be used at exceptional cases where low reflectance or contrasts

are present in the task, errors are costly to rectify, visual work is critical, accuracy or higher productivity

is of great importance and the visual capacity of the worker makes it necessary.

Similarly, lower value (L) of the range may be used when reflectances or contrasts are unusually high,

speed and accuracy is not important and the task is executed only occasionally.

Recommended Illumination

The following Table 8.2 gives the recommended illuminance range for different tasks and activities

for chemical sector. The values are related to the visual requirements of the task, to user’s satisfaction,

to practical experience and to the need for cost effective use of energy (Source IS 3646 (Part I): 1992).

For recommended illumination in other sectors, reader may refer illuminating Engineers Society

Recommendations Handbook.

Table 8.2 Recommended illuminance range for different tasks and activities for chemical

sector .

Methods of Calculating illuminance - Lighting Design for Interiors In order to design a luminaire layout that best meets the illuminance and uniformity requirements of

the job, two types of information are generally needed: average illuminance level and illuminance level

at a given point. Calculation of illuminance at specific points is often done to help the designer evaluate

the lighting uniformity, especially when using luminaires where maximum spacing recommendations

are not supplied, or where task lighting levels must be checked against ambient level.

If average levels are to be calculated, two methods can be applied:1. For indoor lighting situations, the Zonal Cavity Method is used with data from a coefficient

of utilization table.

2. For outdoor lighting applications, a coefficient of utilization curve is provided, the CU is

read directly from the curve and the standard lumen formula is used.

Zonal Cavity Method for Indoor Lighting Calculations

The Zonal Cavity Method (sometimes called the Lumen Method) is the currently accepted method for

calculating average illuminance levels for indoor areas, unless the light distribution is radically

asymmetric. It is an accurate hand method for indoor applications because it takes into consideration

the effect that inter-reflectance has on the level of illuminance.

Although it takes into account several variables, the basic premise that foot-candles are equal to

luminous flux over an area is not violated.

The basis of the Zonal Cavity Method is that a room is made up of three spaces or cavities. The space

between the ceiling and the fixtures, if they are suspended, is defined as the “ceiling cavity”; the space

between the work plane and the floor, the “floor cavity”; and the space between the fixtures and the

work plane, the “room cavity.”

Example:

The step by step process of lighting design is illustrated below with the help of an example. The Figure

8.13 shows the parameters of a typical space.

Step-1: Decide the required illuminance on work plane, the type of lamp and luminaire

A preliminary assessment must be made of the type of lighting required, a decision most often made as

a function of both aesthetics and economics. For normal office work, illuminance of 200 lux is desired.

For an air conditioned office space under consideration, we choose 36 W fluorescent tube lights with

twin tube fittings. The luminaire is porcelain-enameled suitable for the above lamp. It is necessary to

procure utilisation factor tables for this luminaire from the manufacturer for further calculations.

Step-2: Collect the room data in the format given below

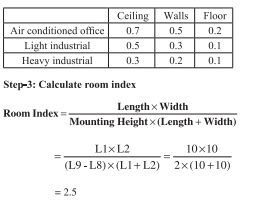

Typical reflectance values for using in L5, L6, L7 are:

Step 4: Calculate the utilisation factor

Utilisation factor is defined as the percent of rated bare-lamp lumens that exit the luminaire and reach

the work plane. It accounts for light directly from the luminaire as well as light reflected off the room

surfaces. Manufacturers will supply each luminaire with its own CU table derived from a photometric

test report.

Using tables available from manufacturers, it is possible to determine the utilisation factor for different

light fittings if the reflectance of both the walls and ceiling is known, the room index has been determined

and the type of luminaire is known. For twin tube fixture, utilisation factor is 0.66, corresponding to

room index of 2.5.

Step-5: To calculate the number of fittings required, the following formula is used Where, MF = Maintenance Factor

Typical LLF values

A

So, 6 Numbers of Twin Tube Fixtures are required. Total number of 36 W lamp is 12. Step 6: Space the luminaires to achieve desired uniformity

Every luminaire will have a recommended space to height

ratio. In earlier design methodologies, the uniformity ratio,which is the ratio of minimum illuminance to average illuminance, was kept at 0.8 and suitable space to height

ratio is specified to achieve the uniformity. In modern

designs incorporating energy efficiency and task lighting, the emerging concept is to provide a uniformity of 1/3 to

1/10 depending on the tasks.

Recommended value for the above luminaire is 1.5. If the actual ratio is more than the recommended

values, the uniformity of lighting will be less.

For a sample of arrangement of fittings, refer Figure 8.14. The luminaire closer to a wall should be

one half of spacing or less.

Luminaire Spacing

Spacing between luminaires = 10/3 = 333m

Mounting height (L9-L8) = 2.0m

Space to height ratio (SHR) = 3.33/2.0 = 1.66

This is close to the limits specified and hence accepted.

It is better to choose luminaires with larger SHR. This can reduce the number of fittings and connected

lighting load.

General Energy Saving Opportunities

Changing the light bulbs is not the only way to improve the use of lighting. Below are some examples

of many other options available:

a) Use natural day lighting The utility of using natural day lighting instead of electric lighting during the day is well known, but

is being increasingly ignored especially in modern air-conditioned office spaces and commercial

establishments like hotels, shopping plazas etc. Industrial plants generally use daylight in some fashion,

but improperly designed day lighting systems can result in complaints from personnel or supplementary

use of electric lights during daytime.

Some of the methods to incorporate day lighting are:

i. North lighting by use if single-pitched truss of the saw-tooth type is a common industrial

practice; this design is suitable for latitudes north of 23 i.e. in North India. In South India,

north lighting may not be appropriate unless diffusing glasses are used to cut out the direct

sunlight.

il. Innovative designs are possible which eliminates the glare of daylight and blend well with

the interiors. Glass strips, running continuously across the breadth of the roof at regular

intervals, can provide good, uniform lighting on industrial shop floors and storage bays.

ill.A good design incorporating sky lights with FRP material along with transparent or translucent

false ceiling can provide good glare-free lighting; the false ceiling will also cut out the heat

that comes with natural light.

iV. Use of atrium with FRP dome in the basic architecture can eliminate the use of electric lights

in passages of tall buildings.

V.Natural Light from windows should also be used. However, it should be well designed to

avoid glare. Light shelves can be used to provide natural light without glare.

vi. Mounting Solar tube on the roof, with the help of advanced optics and special duct work to

direct sunlight deep into the buildings and spreading out over large internal spaces providing

heat and glare free daylighting for 8-10 hrs in a day.

b) De-lamping to reduce excess lighting

De-lamping is an effective method to reduce lighting energy consumption. In some industries, reducing

the mounting height of lamps, providing efficient luminaires and then de-lamping has ensured that the

illuminance is hardly affected. De-lamping at empty spaces where active work is not being performed

is also a useful concept.

c) Task lighting

Task Lighting implies providing the required good illuminance only in the actual small area where the

task is being performed, while the general illuminance of the shop floor or office is kept at a lower

level; e.g. Machine mounted lamps or table lamps. Energy saving takes place because good task lighting

can be achieved with low wattage lamps. The concept of task lighting if sensibly implemented, can

reduce the no of general lighting fixtures, reduce the wattage of lamps, save considerable energy and

provide better illuminance and also provide aesthetically pleasing ambience.

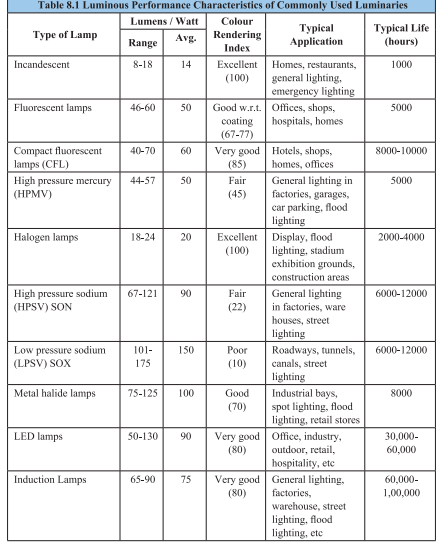

d) Selection of high efficiency lamps and luminaries

The details of common types of lamps are summarised in Table 8.1 above. It is possible to identify

energy saving potential for lamps by replacing with more efficient types. The following examples of

lamp replacements are common. There may be some limitations if colour rendering is an important

factor. It may be noted that, in most cases, the luminaires and the control gear would also have to be

changed. The savings are large if the lighting scheme is redesigned with higher efficacy lamps and

luminaires.

e) Reduction of lighting feeder voltage

Figure 8.15 shows the effect of variation of voltage on light output and power consumption for

fluorescent tube lights. Similar variations are observed on other gas discharge lamps like mercury

vapour lamps, metal halide lamps and sodium vapour lamps (Table 8.3 summarises the effects). Hence

reduction in lighting feeder voltage can save energy, provided the drop in light output is acceptable.

In many areas, night time grid voltages are higher than normal; hence reduction in voltage can save

energy and also provide the rated light output. Some manufacturers are supplying reactors and

transformers as standard products. A large number of industries have used these devices and have

reported saving to the tune of 5% to 15%. Industries having a problem of higher night time voltage

can get an additional benefit of reduced premature lamp failures.

f) Electronic ballasts

Conventional electromagnetic ballasts (chokes) are used to provide higher voltage to start the tube

light and subsequently limit the current during normal operation. Electronic ballasts are oscillators

that convert the supply frequency to about 20,000 Hz to 30,000 Hz. The basic functions of electronic

ballast are:

¢ To ignite the lamp

¢ To stabilize the gas discharge

¢ To supply the power to the lamp

The losses in electronic ballasts for tube lights are only about 1 Watt, in place of 10 to 15 Watts in

standard electromagnetic chokes.

The additional advantage is that the efficacy of tube lights improves at higher frequencies, resulting

in additional savings if the ballast is optimised to provide the same light output as with the conventional

choke. Hence a saving of about 15 to 20 Watts per tube light can be achieved by use of electronic

ballasts. With electronic ballast, the starter is eliminated and the tube light lights up instantly without

flickering.

g) Lighting controllers

Automatic control for switching off unnecessary lights can lead to good energy savings. This includes

dimmers, motion & occupancy sensors, photosensors and timers.

h) Lighting maintenance

Maintenance is vital to lighting efficiency. Light levels decrease over time because of aging lamps and

dirt on fixtures, lamps and room surfaces. Together, these factors can reduce total illumination by 50

percent or more, while lights continue drawing full power. The basic maintenance includes cleaning

of lamps and fixtures, cleaning and repainting interiors, relamping etc

Energy Efficient Lighting Controls

Occupancy Sensors

Occupancy-linked control can be achieved using infra-red, acoustic, ultrasonic or microwave sensors,

which detect either movement or noise in room spaces. These sensors switch lighting on when

occupancy is detected, and off again after a set time period, when no occupancy movement detected.

They are designed to override manual switches and to prevent a situation where lighting is left on in

unoccupied spaces. With this type of system it is important to incorporate a built-in time delay, since

occupants often remain still or quiet for short periods and do not appreciate being plunged into darkness

if not constantly moving around.

Timed Based Control

Timed-turnoff switches are the least expensive type of automatic lighting control. In some cases, their

low cost and ease of installation makes it desirable to use them where more efficient controls would

be too expensive.

Types and features

The oldest and most common type of timed-turnoff switch is the “dial timer,” a spring-wound mechanical

timer that is set by twisting the knob to the desired time. Typical units of this type are vulnerable to

damage because the shaft is weak and the knob is not securely attached to the shaft. Some spring wound units make an annoying ticking sound as they operate. Newer types of timed-turnoff switches

are completely electronic and silent. Electronic switches can be made much more rugged than the spring-wound dial timer. These units typically have a spring-loaded toggle switch that turns on the

circuit for a preset time interval. Some electronic models provide a choice of time intervals, which

you select by adjusting a knob located behind the faceplate. Most models allow occupants to turn off

the lights manually. Some models allow occupants to keep the lights on, overriding the timer. Timed�turnoff switches are available with a wide range of time spans. The choice of time span is a compromise.

Shorter time spans waste less energy but increase the probability that the lights will turn off while

someone is in the space. Dial timers allow the occupant to set the time span, but this is not likely to

be done with a view toward optimising efficiency. For most applications, the best choice is an electronic

unit that allows the engineering staff to set a fixed time interval behind the cover plate.

Daylight Linked Control

Photoelectric cells can be used either simply to switch lighting on and off, or for dimming. They may

be mounted either externally or internally. It is however important to incorporate time delays into the

control system to avoid repeated rapid switching caused, for example, by fast moving clouds. By using

an internally mounted photoelectric dimming control system, it is possible to ensure that the sum of

daylight and electric lighting always reaches the design level by sensing the total light in the controlled

area and adjusting the output of the electric lighting accordingly. If daylight alone is able to meet the

design requirements, then the electric lighting can be turned off. The energy saving potential of dimming

control is greater than a simple photoelectric switching system. Dimming control is also more likely

to be acceptable to room occupants.

Localized Switching

Localized switching should be used in applications which contain large spaces. Local switches give

individual occupants control over their visual environment and also facilitate energy savings. By using

localized switching it is possible to turn off artificial lighting in specific areas, while still operating it

in other areas where it is required, a situation which is impossible if the lighting for an entire space is

controlled from a single switch.

Street Lighting Systems and Controls

Street lighting /Public lighting is one of the major electrical loads in municipal areas. Number of street

lights used in a Municipal area varies from 20000 — 50000 in numbers depending on the kilometers

of road illuminated within the municipal limits. Typical electrical load of municipal lighting system

varies 2MW to 7 MW. The type of lamps used in Municipal area includes Fluorescent Tube light/

Mercury Vapor Lamps/ Sodium Vapor Lamps and Metal Halide Lamps. High Mast towers are also

used at strategic junctions in the Municipal area. LEDs are also used for traffic signaling purpose in

municipal areas.

Following controls are adopted to reduce energy consumption in street lighting system:

1. Timer control (Switch ON/OFF as per set timing)

2. Day light control(Based on illumination level)

3. Selective switching/Alternate switching of street lights low traffic density areas (after

midnight).

4. Switching control based on lux levels. (after midnight)

5. Installations of Voltage controllers to be operated after midnight.

6. Installation of PLC controlled Lighting panels for effective control and monitoring.

Standards and Labeling Programs for FTL Lamps

Considering the large number of fluorescent lamps (FTL) in usage, BEE has included FTL under

Standard and Labeling Programme (S&L). The S&L Programme covers 4 feet tubular fluorescent

lamps (101mm) for wattages up to 40W. The S&L programme includes 6500K colour temperature

for halo-phosphates and 6500K, 4000K & 2700K for tri-phosphate category. The star rating scheme

for FTL is given in Table 8.4.

Table 8.4 Star Rating scheme for FTL (101 mm)

Replacement of existing T12 Fluorescent lamps in street lighting system with LED lamps

Existing: Fluorescent lamp (T12) fixture of 40 numbers is connected to the entire campus for security

purpose. All the lights remain in operation for around 12 hours at night (6 p.m. to 6 am) every day

throughout the year. All the light fixtures are equipped with electromagnetic ballast which consumes

around 12 to 14 watt of additional power while in operation. Hence the power consumption of a single

fluorescent light fixture considering minimum ballast loss is 40+12=52 watts. The total light output

of all the fluorescent light fixtures is around 2400 lumen.

Proposed: It was proposed to replace existing lamps with high efficient LED lamps of 18 W with a

luminous efficacy of around 120-140 Im/w. The total luminous output of these lamps is around 2340

lumen.

Comments

Post a Comment