ENERGY_PERFORMANCE_ASSESSMENT_FOR_EQUIPMENT_AND_UTILITY_SYSTEMS_(Chapter 3:Energy Performance Assessment of Cogeneration Systems With Steam & Gas turbine)

ENERGY_PERFORMANCE_ASSESSMENT_FOR_EQUIPMENT_AND UTILITY SYSTEMS

(Chapter 3:Energy Performance Assessment of Cogeneration Systems With Steam & Gas turbine)

Introduction

Cogeneration systems can be broadly classified as those using steam turbines, Gas turbines and DG sets. Steam turbine cogeneration systems involve different types of configurations with respect to mode of power generation such as extraction, back pressure or a combination of backpressure, extraction and condensing.

Gas turbine with heat recovery steam generators is another mode of cogeneration. Depending on power and steam load variations in the plant the entire system is dynamic. A performance assessment would yield valuable insights into cogeneration system performance and need for further optimization.

Purpose of the Performance Test

The purpose of the cogeneration plant performance test is to determine the power output and plant heat rate. In certain cases, the efficiency of individual components like steam turbine is addressed specifically where performance deterioration is suspected. In general, the plant performance will be compared with the base line values arrived at for the plant operating condition rather than the design values. The other purpose of the performance test is to show the maintenance accomplishment after a major overhaul. In some cases the purpose of evaluation could even be for a total plant revamp.

Performance Terms and Definitions

Overall Plant Performance

Steam Turbine PerformanceGas Turbine and Heat Recovery Steam Generator Performance

Reference Standards

ASME performance test codes

Field Testing Procedure

The test procedure for each cogeneration plant will be developed individually taking into consideration the plant configuration, instrumentation and plant operating conditions.

Test Duration

The test duration is site specific and in a continuous process industry, 8-hour test data should give reasonably reliable data. In case of an industry with fluctuating electrical/steam load profile, a set of 24-hour data sampling to be taken for a representative period.

Measurements and Data Collection

The suggested instrumentation (online/ field instruments) for the performance measurement is as under:

Steam flow measurement : Orifice flow meters

Fuel flow measurements : Volumetric measurements / Mass flow meters

Air flow / Flue gas flow : Venturi / Orifice flow meter / Ion gun / Pitot tubes

Flue gas analysis : Zirconium Probe Oxygen analyser

Unburnt analysis : Gravimetric analysis

Temperature : Thermocouple

Cooling water flow : Orifice flow meter / weir /channel flow/

non-contact flow meters

Pressure : Bourdon Pressure Gauges

Power : Trivector meter / Energy meter

Condensate : Orifice flow meter

It is essential to ensure that the data is collected during steady state plant running conditions. Among others the following are essential details to be collected for cogeneration plant performance evaluation.

I. Thermal Energy:

II. Electrical Energy:

1. Total power generation for the trial period from individual turbines.

2. Hourly average power generation

3. Quantity of power import from utility ( Grid )

4. Auxiliaries power consumption

Calculations for Steam Turbine Cogeneration System

The process flow diagram for cogeneration plant is shown in Figure 3.1. The following calculation procedures have been provided in this section.

1.Turbine cylinder efficiency

2.Overall plant heat rate

Step 3:

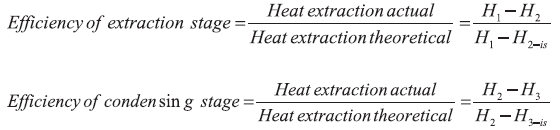

Compute turbine stage (isentropic) efficiency

Calculation of power generation potential

1. Kiln capacity: 4300 Tons per Day (179.167 Tons Per Hour)

2. No of stages in the preheater: 5

3. Preheater exit gas details:

Volume (mph): 167559 Nm3/hr

Specific heat capacity (Cph) : 0.355 kcal/kg/ Deg C

Inlet Temperature T: 295 Deg C

Outlet temperature with WHRB: 195 Deg C

4. Cooler exit gas details:

Volume (mc) : 91000 Nm3/hr

Specific heat capacity (Cc) : 0.316 kcal/kg/ Deg C

Inlet Temperature T: 360 Deg C

Outlet temperature with WHRB: 130 Deg C

5. Overall Conversion efficiency —Pre heater section: 20%

6. Overall Conversion efficiency- Cooler section: 21 %

Calculations:

Solved Example:

A common plant facility is installed to provide steam and power to textile and paper plant with a cogeneration system. The details and operating parameters are given below:

Other data:

- Turbine, alternator and other losses = 8%

- Specific steam consumption in paper industry= 5 Tons/Ton of paper

- Specific power consumption in paper industry= 600 kWh/Ton of paper

Calculate:

i. Coal consumption in boiler per hour or per day.

il. Power generation from co-generation plant

iil. If 10% is auxiliary power consumption in co-generation plant, how much power is consumed

by the textile industry per hour?

iv. What is the gross heat rate of turbine?

ii) Gross power generation from co-generation plant

Total enthalpy input to turbine = 60,000 x 810 = 48.6 Million kcal.

Total enthalpy out put through back pressure = 60,000* 660 = 39.6 Million kcal

Enthalpy difference = 48.6- 39.6 =9 Million kcal/hr

Turbine, alternator and other losses (8%) = 9x0.08 = 0.72 Million kcal/hr

Useful energy for power generation = 9 - 0.72 = 8.28 Million kcal/hr

Power generation from co-generation plant = 8.28 x 10°/860 = 9628 kWh

il) If 10% is auxiliary power consumption in co-generation plant, power consumed by textile

industry

10% of total power generation = 9628 x 0.10 = 962.8 kWh

Total power consumed by industries = 9628 — 962.8 = 8665.2 kWh

Total steam consumption in paper plant 40 tons/hr. and specific steam consumption 5 ton/ton

of paper. So Paper production per hour is 8 tons.

Specific power consumption = 600kWh/ton.

Total power consumption in paper industry = 8 x 600 = 4800kWh

Total power consumption in textile industry = 8665.2- 4800 = 3865.2 kWh

iv) Gross heat rate =Input enthalpy — Output enthalpy/ Gross generation

= (48.6- 39.6) 10°/ 9628

= 934.7 keal/kWh

-----------------------

Chapter 4

Comments

Post a Comment