ENERGY_PERFORMANCE_ASSESSMENT_FOR_EQUIPMENT_AND_UTILITY_SYSTEMS

(Chapter 1: ENERGY PERFORMANCE ASSESSMENT OF BOILERS)

Introduction

Performance of the boiler, like efficiency and evaporation ratio reduces with time, due to poor combustion, heat transfer fouling and poor operation and maintenance. Deterioration of fuel quality and water quality also leads to poor performance of boiler. Efficiency testing helps us to find out how far the boiler efficiency drifts away from the best efficiency. Any observed abnormal deviations could therefore be investigated to pinpoint the problem area for necessary corrective action. Hence it is necessary to find out the current level of efficiency for performance evaluation, which is a prerequisite for energy conservation action in industry.

Purpose of the Performance Test

¢ To find out the efficiency of the boiler

¢ To find out the evaporation ratio

The purpose of the performance test is to determine actual performance and efficiency of the boiler and compare it with design values or norms. It is an indicator for tracking day-to-day and season-toseason variations in boiler efficiency and energy efficiency improvements.

Performance Terms and Definitions

Scope

The procedure describes routine test for both oil fired and solid fuel fired boilers using coal, agro residues etc. Only those observations and measurements need to be made which can be readily applied

and is necessary to attain the purpose of the test.

Reference Standards

British standards, BS845: 1987

The British Standard BS845: 1987 describes the methods and conditions under which a boiler should be tested to determine its efficiency. For the testing to be done, the boiler should be operated under steady load conditions (generally full load) for a period of one hour after which readings would be taken during the next hour of steady operation to enable the efficiency to be calculated. The efficiency of a boiler is quoted as the % of useful heat available, expressed as a percentage of the total energy potentially available by burning the fuel. This is expressed on the basis of gross calorific value (GCV).

This deals with the complete heat balance and it has two parts:

¢ Part One deals with standard boilers, where the indirect method is specified

¢ Part Two deals with complex plant where there are many channels of heat flow. In this case,

both the direct and indirect methods are applicable, in whole or in part.

ASME Standard: PTC-4-1 Power Test Code for Steam Generating Units

This consists of

¢ Part One: Direct method (also called as Input -output method)

¢ Part Two: Indirect method (also called as Heat loss method)

IS 8753: Indian Standard for Boiler Efficiency Testing

Most standards for computation of boiler efficiency, including IS 8753 and BS845 are designed for spot measurement of boiler efficiency. Invariably, all these standards do not include blow down as a loss in the efficiency determination process.

Basically Boiler efficiency can be tested by the following methods:

1) The Direct Method: Where the energy gain of the working fluid (water and steam) is compared with the energy content of the boiler fuel.

2) The Indirect Method: Where the efficiency is the difference between the losses and the energy input.

The Direct Method Testing

Description

This is also known as ‘input-output method’ due to the fact that it needs only the useful output (steam) and the heat input (i.e. fuel) for evaluating the efficiency. This efficiency can be evaluated using the formula:

Measurements Required for Direct Method Testing

Heat input

Both heat input and heat output must be measured. The measurement of heat input requires knowledge of the calorific value of the fuel and its flow rate in terms of mass or volume, according to the nature of the fuel.

For gaseous fuel: A gas meter of the approved type can be used and the measured volume should be corrected for temperature and pressure. A sample of gas can be collected for calorific value determination, but it is usually acceptable to use the calorific value declared by the gas suppliers.

For liquid fuel: Heavy fuel oil is very viscous, and this property varies sharply with temperature. The meter, which is usually installed on the combustion appliance, should be regarded as a rough indicator only and, for test purposes, a meter calibrated for the particular oil is to be used and over a realistic range of temperature should be installed. Even better is the use of an accurately calibrated day tank.

For solid fuel: The accurate measurement of the flow of coal or other solid fuel is very difficult. The measurement must be based on mass, which means that bulky apparatus must be set up on the boiler-house floor. Samples must be taken and bagged throughout the test, the bags sealed and sent to a laboratory for analysis and calorific value determination. In some more recent boiler houses, the problem has been alleviated by mounting the hoppers over the boilers on calibrated load cells, but these are yet uncommon.

Heat output

There are several methods, which can be used for measuring heat output. With steam boilers, an installed steam meter can be used to measure flow rate, but this must be corrected for temperature and pressure. In earlier years, this approach was not favoured due to the change in accuracy of orifice or venturi meters with flow rate. It is now more viable with modern flow meters of the variable-orifice or vortex-shedding types.

The alternative with small boilers is to measure feed water, and this can be done by previously calibrating the feed tank and noting down the levels of water during the beginning and end of the trial. Care should be taken not to pump water during this period. Heat addition for conversion of feed water at inlet temperature to steam, is considered for heat output. In case of boilers with intermittent blowdown, blowdown should be avoided during the trial period. In case of boilers with continuous blowdown, the heat loss due to blowdown should be calculated and added to the heat in steam.

Boiler Efficiency by Direct Method: Calculation and Example

Test Data and Calculation

Water consumption and coal consumption were measured in a coal-fired boiler at hourly intervals. Weighed quantities of coal were fed to the boiler during the trial period. Simultaneously water level difference was noted to calculate steam generation during the trial period. Blow down was avoided during the test. The measured data is given below.

Type of boiler: Coal fired Boiler

Heat output data

Quantity of steam generated (output) : 8 TPH

Steam pressure / temperature : 10 kg/cm? (g)/ 180 °C

Enthalpy of steam (dry & saturated) at 10 kg/em?(g) pressure : 665 kcal/kg

Feed water temperature : 85°C

Enthalpy of feed water : 85 kcal/kg

Heat input data

Quantity of coal consumed (Input) : 1.6 TPH

GCV of coal : 4000 kcal/kg

Merits and Demerits of Direct Method

Merits

« Plant people can evaluate quickly the efficiency of boilers

« Requires few parameters for computation

« Needs few instruments for monitoring

Demerits

« Does not give clues to the operator as to why efficiency of system is lower

* Does not calculate various losses accountable for various efficiency levels

« Evaporation ratio and efficiency may mislead, if the steam is highly wet due to water carryover

The Indirect Method Testing

Description

The efficiency can be measured easily by measuring all the losses occurring in the boilers using the

principles to be described. The disadvantages of the direct method can be overcome by this method,

which calculates the various heat losses associated with boiler. The efficiency can be arrived at, by

subtracting the heat loss fractions from 100.An important advantage of this method is that the errors

in measurement do not make significant change in efficiency.

Thus if boiler efficiency is 90%, an error of 1% in direct method will result in significant change in

efficiency. i.e.90 + 0.9 = 89.1 to 90.9. In indirect method, 1% error in measurement of losses will result

in Efficiency = 100 — (10 + 0.1) = 90 + 0.1 = 89.9 to 90.1

The various heat losses occurring in the boiler are:

Efficiency = 100 - (1+2+3+4+5+64+7+8) (by Indirect Method)

The following losses are applicable to liquid, gas and solid fired boiler

L1- Loss due to dry flue gas (sensible heat)

L2- Loss due to hydrogen in fuel (H,)

L3- Loss due to moisture in fuel (H,O)

L4- Loss due to moisture in air (H,O)

L5- Loss due to carbon monoxide (CO)

L6- Loss due to surface radiation, convection and other unaccounted*.

*Losses which are insignificant and are difficult to measure.

The following losses are applicable to solid fuel fired boiler in addition to above

L7- Unburnt losses in fly ash (Carbon)

L8- Unburnt losses in bottom ash (Carbon)

Boiler Efficiency by indirect method = 100 — (L1+L2+L3+L4+L5+L6+L7+L8)

Measurements Required for Performance Assessment Testing

The following parameters need to be measured, as applicable for the computation of boiler efficiency

and performance.

a) Flue gas analysis

1. Percentage of CO, or O, in flue gas

2. Percentage of CO in flue gas

3. Temperature of flue gas

b)Flow meter measurements for

1. Fuel

2. Steam

3. Feed water

4. Condensate water

5. Combustion air

c)Temperature measurements for

1. Flue gas

2. Steam

3. Makeup water

4. Condensate return

5. Combustion air

6. Fuel

7. Boiler feed water

d)Pressure measurements for

1. Steam

2. Fuel

3. Combustion air, both primary and secondary

4. Draft

e)Water condition

1. Total dissolved solids (TDS)

2. pH

3. Blow down rate and quantity

The various parameters that were discussed above can be measured with the instruments that are given

in Table 1.1.

Test Conditions and Precautions for Indirect Method Testing

A) The efficiency test does not account for:

* Blow down loss. The amount of energy wasted by blow down varies over a wide range.

* Soot blower steam. The amount of steam used by soot blowers is variable that depends on the

type of fuel.

" Auxiliary equipment energy consumption. The combustion efficiency test does not account

for the energy usage by auxiliary equipments, such as burners, fans, and pumps.

B) Preparations and pre conditions for testing

« Burn the specified fuel(s) at the required rate.

«Do the tests while the boiler is under steady load. Avoid testing during warming up of boilers

from a cold condition

«Obtain the charts / tables for the additional data.

« Determination of general method of operation

« Sampling and analysis of fuel and ash.

« Ensure the accuracy of fuel and ash analysis in the laboratory.

« Check the type of blow down and method of measurement

« Ensure proper operation of all instruments.

* Check for any air infiltration in the combustion zone.

C) Flue gas sampling location

It is suggested that the exit duct of the boiler be probed and traversed to find the location of the zone

of maximum temperature. This is likely to coincide with the zone of maximum gas flow and is therefore a good sampling point for both temperature and gas analysis.

D) Options of flue gas analysis

Check the Oxygen Test with the Carbon Dioxide Test

If continuous-reading oxygen test equipment is installed in boiler plant, use oxygen reading. Occasionally use portable test equipment that checks for both oxygen and carbon dioxide. If the carbon dioxide test does not give the same results as the oxygen test, something is wrong. One (or both) of the tests could be erroneous, perhaps because of stale chemicals or drifting instrument calibration. Another possibility is that outside air is being picked up along with the flue gas. This occurs if the combustion gas area operates under negative pressure and there are leaks in the boiler casing.

Carbon Monoxide Test

The carbon monoxide content of flue gas is a good indicator of incomplete combustion with all types of fuels, as long as they contain carbon. Carbon monoxide in the flue gas is minimal with ordinary amounts of excess air, but it rises abruptly as soon as fuel combustion starts to be incomplete.

E) Planning for the testing

« The testing is to be conducted for a duration of 4 to 8 hours in a normal production day.

« Advanced planning is essential for the resource arrangement of manpower, fuel, water and instrument check etc and the same to be communicated to the boiler Supervisor and Production Department.

« Sufficient quantity of fuel stock and water storage required for the test duration should be arranged so that a test is not disrupted due to non-availability of fuel and water.

« Necessary sampling point and instruments are to be made available with working condition.

« Lab analysis should be carried out for fuel, flue gas and water in coordination with lab personnel.

« The steam table, psychometric chart, calculator are to be arranged for computation of boiler efficiency.

Boiler Efficiency by Indirect Method: Calculation Procedure and Formula

In order to calculate the boiler efficiency by indirect method, all the losses that occur in the boiler must

be established. These losses are conveniently related to the amount of fuel burnt. In this way it is easy to compare the performance of various boilers with different ratings.

However it is suggested to get a ultimate analysis of the fuel fired periodically from a reputed laboratory. Theoretical (stoichiometric) air fuel ratio and excess air supplied are to be determined first for computing the boiler losses. The formula is given below for the same.

The various losses associated with the operation of a boiler are discussed below with required formula.

1. Heat loss due to dry flue gas

This is the greatest boiler loss and can be calculated with the following formula:

Note-1:

For Quick and simple calculation of boiler efficiency use the following.

A: Simple method can be used for determining the dry flue gas loss as given below.

a) Percentage heat loss due to dry flue gas =

Total mass of dry flue gas (m)/kg of fuel = Mass of actual air supplied (ASS) + Mass of fuel

supplied — (M + 9 H,)

Note-2: Water vapour is produced from hydrogen in fuel, moisture present in fuel and air during the combustion. The losses due to these components have not been included in the dry flue gas loss since they are separately calculated as a wet flue gas loss.

2. Heat loss due to evaporation of water formed due to H, in fuel (%)

The combustion of hydrogen causes a heat loss because the product of combustion is water. This water

is converted to steam and this carries away heat in the form of its latent heat.

3. Heat loss due to moisture present in fuel

Moisture entering the boiler with the fuel leaves as a superheated vapour. This moisture loss is made up of the sensible heat to bring the moisture to boiling point, the latent heat of evaporation of the moisture, and the superheat required to bring this steam to the temperature of the exhaust gas. This loss can be calculated with the following formula

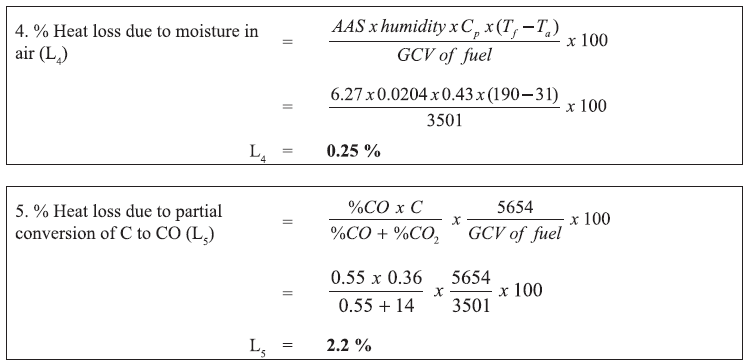

4. Heat loss due to moisture present in air

Vapour in the form of humidity in the incoming air, is superheated as it passes through the boiler. Since this heat passes up the stack, it must be included as a boiler loss. To relate this loss to the mass of coal burnt, the moisture content of the combustion air and the amount of air supplied per unit mass of coal burnt must be known. The mass of vapour that air contains can be obtained from psychrometric charts and typical values are included as follows:

5. Heat loss due to incomplete combustion

Products formed by incomplete combustion could be mixed with oxygen and burned again with a

further release of energy. Such products include CO, H,, and various hydrocarbons and are generally

found in the flue gas of the boilers. Carbon monoxide is the only gas whose concentration can be

determined conveniently in a boiler plant test.

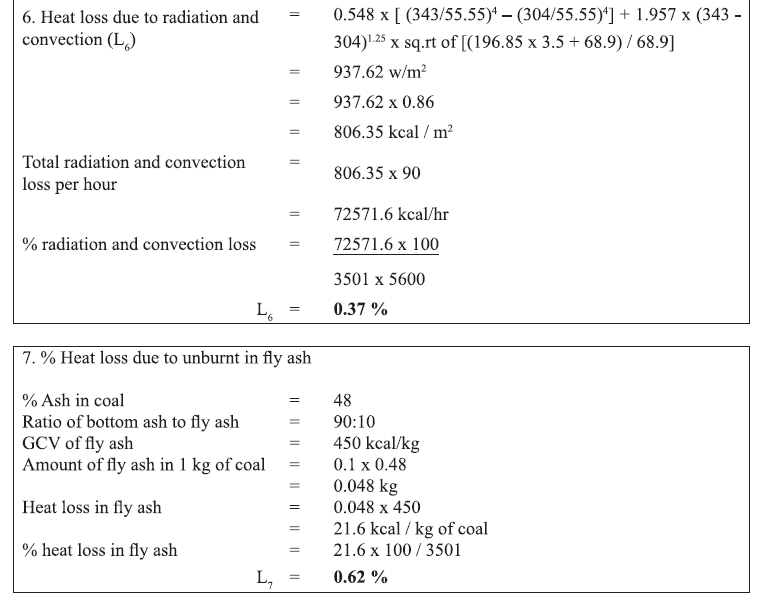

6. Heat loss due to radiation and convection:

The other heat losses from a boiler consist of the loss of heat by radiation and convection from the boiler casting into the surrounding boiler house.

Normally surface loss and other unaccounted losses is assumed based on the type and size of the boiler as given below

For industrial fire tube / packaged boiler = 1.5 to 2.5%

For industrial water tube boiler = 2 to 3%

For power station boiler = 0.4 to 1%

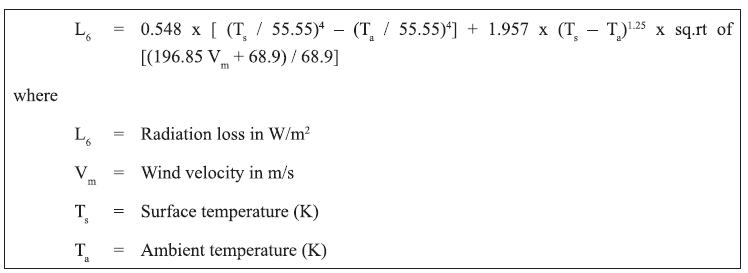

However it can be calculated if the surface area of boiler and its surface temperature are known as

given below :

Heat loss due to unburnt carbon in fly ash and bottom ash:

Small amounts of carbon will be left in the ash and this constitutes a loss of potential heat in the fuel.

To assess these heat losses, samples of ash must be analyzed for carbon content. The quantity of ash

produced per unit of fuel must also be known.

7. Heat loss due to unburnt in fly ash (%):

8. Heat loss due to unburnt in bottom ash (%)

Heat Balance:

Having established the magnitude of all the losses mentioned above, a simple heat balance would give

the efficiency of the boiler. The efficiency is the difference between the energy input to the boiler and

the heat losses calculated.

Example: Boiler Efficiency Calculation For Coal fired Boiler

The following are the data collected for a boiler using coal as the fuel. Find out the boiler efficiency

by indirect method.

Summary of Heat Balance for Coal Fired BoilerNote: Simple method can be used for determining the dry flue gas loss as given below.Percentage heat loss due to dry flue gas =

Total mass of dry flue gas (m)

= Total mass of wet flue gas — Mass of water vapour in flue gas

= Mass of actual air supplied (AAS) + Mass of fuel supplied —(M + 9 H,)

= 21.49 + 1 — {0.005 + (9 x 0.12)} =21.4

% Dry flue gas loss=

=8.22%

Factors Affecting Boiler Performance

The various factors affecting the boiler performance are listed below:

1. Periodical cleaning of boilers

2. Periodical soot blowing

3.Proper water treatment programme and blow down control

4. Draft control

5. Excess air control

6. Percentage loading of boiler

7.Steam generation pressure and temperature

8. Boiler insulation

9.Quality of fuel

All these factors individually/combined, contribute to the performance of the boiler and reflected either

in boiler efficiency or evaporation ratio. Based on the results obtained from the testing further improvements have to be carried out for maximizing the performance. The test can be repeated after

modification or rectification of the problems and compared with standard norms. Energy auditor should carry out this test as a routine manner once in six months and report to the management for necessary action.

Boiler Terminology

MCR: Steam boilers rated output is also usually defined as MCR (Maximum Continuous Rating). This is the maximum evaporation rate that can be sustained for 24 hours and may be less than a shorter

duration maximum rating.

Boiler Rating

Conventionally, boilers are specified by their capacity to hold water and the steam generation rate.

Often, the capacity to generate steam is specified in terms of equivalent evaporation (kg of steam /

hour at 100°C). Equivalent evaporation - “from and at” 100°C. The equivalent of the evaporation of

1 kg of water at 100°C to steam at 100°C.

Primary air: That part of the air supply to a combustion system which the fuel first

encounters.

Secondary air: The second stage of admission of air to a combustion system, generally to complete

combustion initiated by the primary air. It can be injected into the furnace of a boiler under relatively

high pressure when firing solid fuels in order to create turbulence above the burning fuel to ensure

good mixing with the gases produced in the combustion process and thereby complete combustion

Absolute pressure: The sum of the gauge and the atmospheric pressure. For instance, if the steam

gauge on the boiler shows 9 kg/cm?g the absolute pressure of the steam is 10 kg/cm?(a).

Solved Example:

The steam requirement of an export oriented unit (EOU) is met by a 6 TPH oil fired package boiler

generating steam at 10 kg/cm’. The monthly steam consumption of the unit is 3000 tonnes.

Other data are given below:

Fuel oil composition: Carbon = 86%; Hydrogen = 12%; Oxygen= 0.5%; Sulphur =1.5%

Specific heat of flue gases, Cp = 0.27 kcal/kg°C

G.C.V. of fuel oil = 10,000 kcal/kg

Sp. heat of super-heated water vapour =0.45 kcal/kg°C

Enthalpy of steam at 10 kg/cm? = 665kcal/kg

Feed water temperature = 85°C

% O, in dry flue gas = 6%

Flue gas temperature at boiler outlet = 240 °C

Ambient temperature = 30°C

Cost of fuel oil = Rs.43 per kg

Radiation and other unaccounted losses = 2.45%

The export oriented unit is costing its steam cost based on the fuel consumption cost with additional

15% to account for the auxiliary and consumables.

A neighbouring continuous process plant now offers to supply the required steam at 10 kg/cm’ to the

export oriented unit at a cost of Rs 3300 per tonne with a condition that all the condensate will be

returned back.

Calculate the following:

a) Boiler efficiency

b) Cost advantage per tonne of availing steam from neighbouring plant in place of in-house

generation and also monthly monetary saving.

Solution:

First calculate the efficiency of Boiler (in EOU)

Theoretical air required = 11.6 C + 34.8 (H, —O,/8) + 4.35 $

[11.6 X 86 + 34.8 (12 — 0.5/8) + 4.35 X 1.5] x 1/100

= 14.195 = Say 14.2

% Excess Air = [% O,/ (21 - % O,)] X 100

= [6/(21-—6)] X 100= 40%

AAS = Actual amount of air supplied = 14.2 X 1.4

= 19.88 kg per kg of fuel oil

Mass of dry flue gas m dz ~ Mass of combustion gases due to presence of C,H,S +Mass of N, supplied

= (0.86 X 44/12) + (0.015 X 64 / 32) + [(19.88 — 14.2) X 23 / 100] + (19.88 X 77/100)

= 19.797

Mass dry flue gas, say = 19.8 kg / kg fuel

or

Alternatively mass of dry flue gas =(AAS+1)—9H,

= (19.88 +1)-9X0.12 = 19.8 kg/kg fuel

L, = % heat loss in dry flue gas = [Map x Cp x (T, — T,)/ GCV] x 100

= 11.23%

L, = Loss due to presence of hydrogen forming water vapour

L, = Radiation and other unaccounted losses = 2.45%

Total losses = L,+L,+L3

= 11.23+ 7.33 +2.45 = 21.05 %

Efficiency of the EOU boiler by indirect method

= 100 —21.05 =78.99 %

= Say 79 %

Secondly calculate the cost of steam in the EOU plant

= [(0.79 X 10000) / (665 — 85)] X 100

= 13.62 kg Steam / kg Fuel

Fuel oil consumption = 1000/ 13.62 kg per tonne of steam

Fuel oil consumption = 73.42 kg/tonne of steam gen

Cost of fuel oil = Rs. 43 per kg

Cost of steam in EOU = Fuel cost + 15% fuel cost

= 73.42 x 1.15 x 43

= Rs.3,599 per tonne

Say = Rs 3600 per tonne

Selling cost of steam from neighbouring plant = Rs 3300 per tonne

Cost advantage = 3600 — 3300

= Rs.300 per tonne

Annual Savings = Rs.300 per tonne x 3000 tonne/month x 12 month

= Rs. 108 Lakhs

------------------------

Chapter 2

Comments

Post a Comment